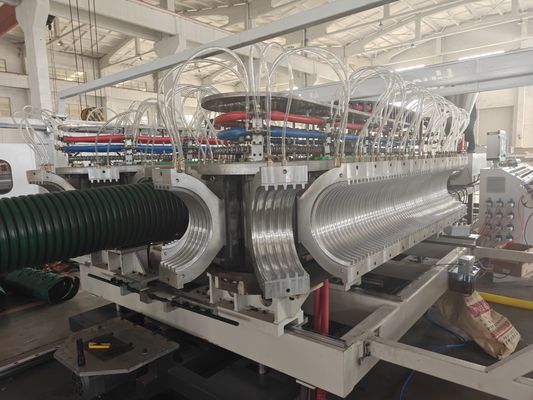

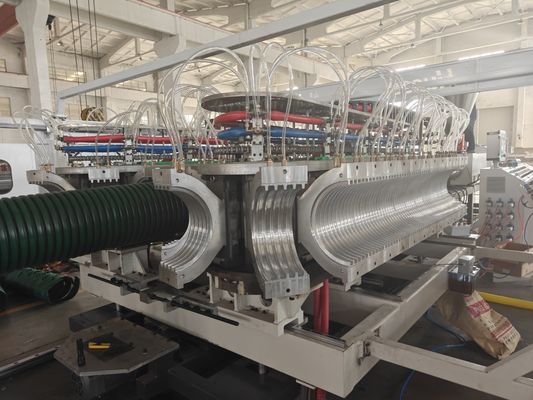

DWC Pipe Extrusion Line with 32-1600mm Cutting Diameter Featuring Siemens PLC Technology and Online Belling for PVC PE MPP PA HDPE Corrugated Pipes

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Cooling Type | Air Cooling And Water Cooling | Expansion Mode | Belling-on-line,double-wall Socket Joint |

|---|---|---|---|

| Processing Procedure | Raw Material Feeding In Screw Extruder, Shaping In Forming Machine ,Water Cooling Tank Cooling,online Cut By Cutting Machine | Product Type | PVC/PE Corrugated Pipe Extrusion Machine |

| Cutting Diameter Range | 32-1600mm | Usage | Corrugated Pipes |

| Corrugator Type | Horizontal | Finished Product | Drainage Pipe,municipal Engineering,underground Sewage Pipe,electric Cable Conduit |

| Highlight | Double Wall Corrugated Tube Extrusion Line,DWC Pipe Making Machine,DWC Corrugated Pipe Extrusion Machine |

||

This third-generation enhanced double wall corrugated pipe extrusion line from Shandong HUASU delivers significant performance improvements over previous models, with extruder output and pipe production speed increased by 20-40%. The advanced design enables seamless online belling, ensuring manufactured corrugated pipes achieve optimal performance characteristics.

- Pressure water-cooling for mould blocks significantly increases production speed

- Low energy consumption reduces production costs

- Efficient vacuum system ensures perfect pipe formation

- Mould block temperature control system optimizes pipe quality and internal structure

- Quick changeover between different mould sizes with compatible tooling

- Fully automatic operation throughout the complete extrusion line

- Synchronous control of corrugators and extruders for efficient production

- Hardened treated screws and barrels for extended lifespan and durability

- Remote service availability for convenient maintenance and support

| Finished Product Applications | Drainage Pipe, Municipal Engineering, Underground Sewage Pipe, Electric Cable Conduit |

|---|---|

| Screw Material | 38 CrMoAla |

| Expansion Mode | Belling-on-line, Double-wall Socket Joint |

| Cutting Diameter Range | 32-1600mm |

| Cooling Type | Air Cooling And Water Cooling |

| Corrugator Type | Horizontal |

| Product Type | PVC/PE Corrugated Pipe Extrusion Machine |

| Processing Procedure | Raw Material Feeding In Screw Extruder, Shaping In Forming Machine, Water Cooling Tank Cooling, Online Cut By Cutting Machine |

| Key Features | High Productivity, Competitive Price, Energy Saving, Automatic |

| Compatible Materials | PVC / PE / MPP / PA / HDPE |

Our plastic pipe making machine efficiently manufactures plastic pipes for diverse applications including:

- Water supply systems

- Drainage systems

- Electric cable conduits

- Municipal engineering projects

- Underground sewage systems