Agriculture Plastic Pipe Extrusion Line, Plastic Tube Extrusion Machine For Making Water Drainage Pipes

1. 160-450mm PE Pipe Extrusion machine is mainly used for producing gas supplying pipe, water supplying pipe, cable protection pipe etc.

2. The pipe has some excellent features such as low temperature impact resistance, reliable connection, good stress crack resistance, good chemical resistance, good wear resistance, long using life, etc. our extrusion line is designed with high efficiency extruder and equipped with reducer which is high speed and low noise.

3. Gravimetric dosing unit and ultrasonic thickness indicator can be assembled according to customer's demand to ascend the precise of the pipes .

4. Turn key solution can be provided, like laser printer crusher, shredder, water chiller, air compressor etc. to achieve high-grade and automatic tube production.

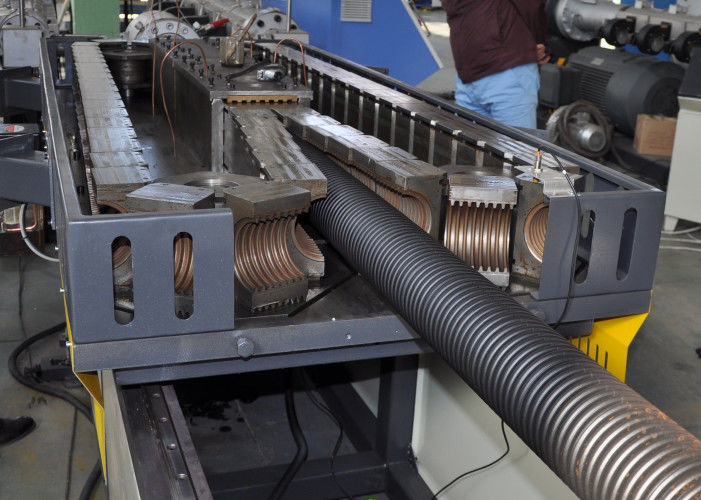

Characteristics of electric conduit pipe machine

1 . one die double out or four out, it greatly increase the productivity, meantime, it reduces the cost of machine, power consumption, save space of workshop

2 . Speed of extruding, haul off machine are controlled by variable frequency inverter, stepless adjusting speed and save power consumption

3 . Water cooling tank are made of high qulity 304 stainless steel, no rusty, longer lifetime.

4 . Temperature controlled by intelligent temperature controller, high precision, automatic control, save labor and easy to operate.

Process Flow

Raw material+ Master Batches → Mixing → Vacuum Feeder →Plastic Hopper Drier→ Single Screw Extruder →Co-extruder for color string & Multi Layers → Mould → Vacuum Calibration Tank → Spray Cooling Water Tank → Haul-off → No Dust Cutter →Stacker → Final Product→ Inspecting &Packing

Applications

| 1 |

High efficiency PP-R PE-RT PB pipes are widely used in the uptown apartment and village cables protection hot water supplying house heating. |

| 2 |

This production line adopts high efficiency single screw extruder equipped with the Siemens PLC controlling system. |

| 3 |

It can ensure the whole line automatic controlling of high capacity stable extruding with the suitable changing of different units could realize the production job of PP-R PE-RT PB pipe. |

Main technical parameter of PE pipe production line

| Model |

Pipe range(mm) |

Extruder Model |

| SBG-63 |

Φ20-63 |

SJ65/33 or SJ65/38 |

| SBG-63(Double outlet) |

Φ20-63 |

SJ65/38 |

| SBG-110 |

Φ20-110 |

SJ65/33 or SJ65/38 |

| SBG-110(Double outlet) |

Φ20-110 |

SJ75/38 |

| SBG-160 |

Φ50-160 |

SJ75/33 or SJ75/38 |

| SBG-250 |

Φ90-250 |

SJ75/33 or SJ75/38

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!