PE Plain Wall Pipe Making Extrusion Line and Machine for Making PE Solid Wall Pipe

General information

- Special request from Customer:

- Products:

- Application: Threading, ventilation, drainage

- Pipe length: According the customer’s inquiry

- Recommended raw material: new material for PE

- Pipe list and pressure grade:

| Diameter(mm) |

20 |

25 |

32 |

40 |

50 |

63 |

| Pressure grade |

|

|

|

|

|

|

| Location |

Workshop |

| Power Supply |

No dangerous area, No power stop area |

| Humidity degree |

≤95% |

| Temperature |

0-36℃ |

| Power |

380 V x 50 Hz x 3 Phase (according to customer requirement) |

| Total Power |

140kw,energy consumption is about 85kw |

| Cooling Water |

Recycling water. ≤20℃, ≥0.3Mpa, ~15M³/h |

| Compressed air |

0.3m3/min, >1.2Mpa |

| Outline dimension |

42m×2.2m×2.5m |

- Main Technical Performance

| Extruder |

Motor |

Max. Output |

Note |

| SJ65/33 |

75kw |

220kg/h |

Extrusion for pipe |

| SJ30/25 |

2.2kw |

10kg/h |

Extrusion for mark |

1. The output capacity varies with the materials and the operation conditions.

2. Line speed: According to the thickness, pipe standard and operation condition.

3. Operation direction:From Right to Left.

4. The color of the line:HUASU standard color.

5. Remains the right to improve the specification of the line, if there is any modification in the future customer will not be informed.

Detailed technical information

| No |

Name |

Model |

Qty |

Remark |

| 1.0 |

Single screw extruder |

SJ65×33 |

1 set |

Extrusion for pipe |

| Single screw extruder |

SJ30×25 |

1 set |

Extrusion for mark |

| 2.0 |

Molds |

|

1 set |

|

|

3.0

|

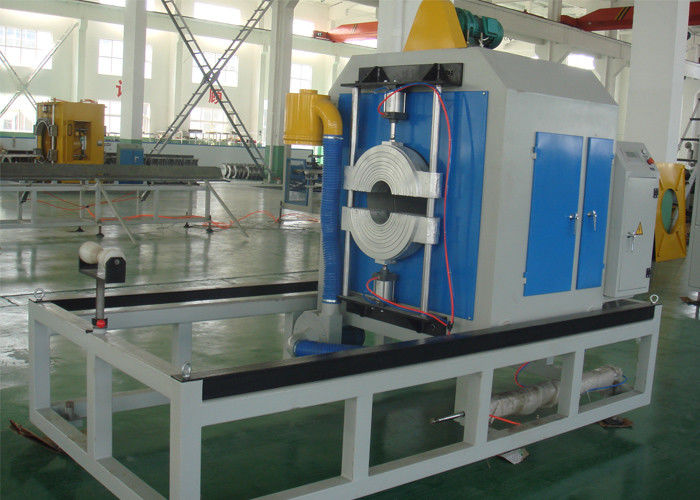

Vacuum calibration water cooling tank |

SGZL-63 |

1 set |

3000mm |

| Vacuum calibration water cooling tank |

SGZL-63 |

1 set |

6000mm |

| 4.0 |

Spray water tank |

SGPL-63 |

2 sets |

|

| 5.0 |

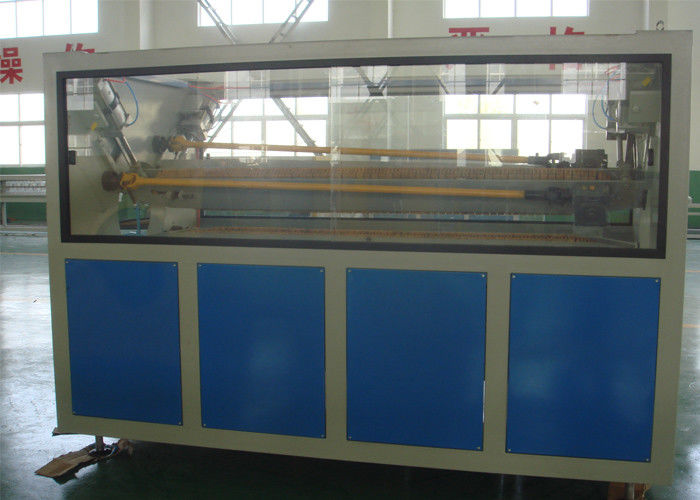

Haul-off machine |

SDQ-63 |

1 set |

|

| 6.0 |

Cutting machine |

SGQG-63 |

1 set |

|

| 7.0 |

Overturn bracket |

|

1 set |

|

| 8.0 |

Control system |

|

1 set |

|

1.1 Single Screw Extruder SJ30×25

--Screw hardness of screw HV>740

--Barrel hardness of barrel HV>940

--Material 38CrMoALA, nitriding handling

--Barrel nitriding depth 0.5~0.7mm

--Screw nitriding depth 0.4~0.6mm

--Slotted barrel with water-cooled forced feeding

--Screw diameter 30mm

--L: D 25:1

Heating & cooling

--Barrel heating zone 3 zones × 1kw

--Barrel power 3kw

Driving

--AC Motor 2.2kw

--Reducer Planetary cycloid reducer

--Hopper material Stainless steel hopper

2.0 Molds

--Specification Φ20-63mm

--Structure Spiral split structure design

--Material 40 Cr Forging and tempering treatment

--Heating method Stainless steel heating ring

--Heating power 12kw

2.1 Die/Core/Sizing sleeve

--Water film sizing sleeve

--Material copper

--Specification Φ20,Φ25,Φ32,Φ40,Φ50,Φ63

3.0 Vacuum calibration water cooling SGZL-63

--Applicable pipe range Φ20-63mm

--Cabinet material stainless steel plate spray paint

--Vacuum box length 3000mm

--Vacuum pump 3KW

--Water pump 2.2KW

--Maximum vacuum -0.06MPa

--Stainless steel filter

--Spray pipe 4 pcs stainless steel

--Nozzle ABS

--Water temperature and water level automatic control system

--Electrical control box hanging type

--Three-dimensional adjustable cabinet

--Moving forward and backward motor 0.75KW

--Height, horizontal manual control

--Front and back movement distance of the box 900mm

--Left and right adjustment distance of the box ±50mm

--Up and down adjustment distance of the box ±50mm

--Ground rail square steel pipe with painting

3.1 Vacuum calibration water cooling SGZL-63

--Applicable pipe range Φ20-63mm

--Cabinet material stainless steel plate spray paint

--Vacuum box length 6000mm

--Vacuum pump 4KW

--Water pump 4KW

--Maximum vacuum -0.06MPa

--Stainless steel filter

--Spray pipe 4 pcs stainless steel

--Nozzle ABS

--Water temperature and water level automatic control system

--Electrical control box hanging type

--The height of cabinet can be adjusted from left to right

--Up and down adjustment distance of the box ±50mm

4.0 Spray water tank SGPL-63

--Tank body stainless steel

--Water pump 4KW

--Length 6000mm

--Spraying pipe 4 pieces stainless steel

--Nozzle ABS

--Height adjustable

--Up and down adjustment distance of the box ±50mm

5.0 Haul-off machine SDQ-63

--Type Two pedrails

--Rubber block material soft elastic V-shaped rubber block

--Clamping tube form pneumatic

--Clamping tube length 2200mm

--Drive motor power 3kw frequency conversion speed regulation

--Hauling-off tension (max). 3KN

--Hauling speed 3-30m/min

6.0 Cutting machine SGQG-63

--Application range Φ20~Φ63mm

--Clamping method Pneumatic clamping

--Blade material alloy blade

--Cutting form circular cutting

--Working linear velocity 0.3-5 M/min

--Effective stroke length 1500mm

--Revolution motor power 1.1kw

7.0 Overturn bracket STF-6000

--Unloading pipe length 6000mm

--Flap material stainless steel polishing

--Pneumatic control, automatic overturn with fixed length

8.0 Control system

--temperature control Omron

--Inverter ABB

--Contactor Siemens

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews