200-600mm PE PP PVC Corrugated Pipe Extrusion Line Details With Price And Introduction

Starting a corrugated pipe plant is great! And the following reasons prove this:

Material saving

When you manufacture corrugated pipes, you save up to 60% of raw materials had you gone with solid walled pipes.

Though they are lighter, these pipes are strengthen by the rings in their structure.

Easy handling

Corrugated pipes are lighter, which makes them easy to handle and transport.

So you will require less personnel for your corrugated plant and the same benefits will trickle down to the end user.

Less ecological footprint

By cutting down on the material used, your factory will have far less impact on the environment.

In addition, manufacturing corrugated pipes produces less carbon iv oxide emission compared to making concrete pipes.

What’s more, you can recycle corrugated pipes them.

Conclusion

In this chapter, I have introduced you to corrugated pipes. And why you a manufacture you should consider making them.

Join me in next chapter as we get more technical and discover different aspects of the corrugated pipe extrusion machine.

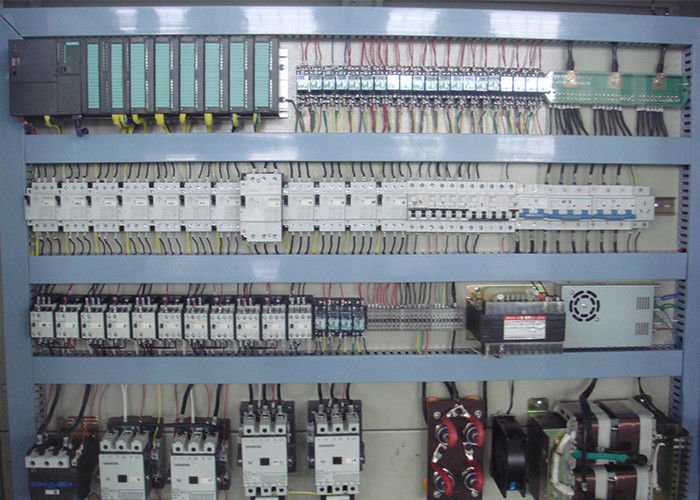

At first the corrugated Pipe making line may look complex.

But, you can easily understand all the parts of the corrugated pipe production line along with the processes taking place in each machine.

Generally, we have the following processes occurring:

Preparation of raw materials

Extrusion

Corrugation

Cooling

Finishing/cutting

Preparation of the raw materials

You will start by ordering raw materials from different suppliers.

Once the raw materials arrive at your factory, the quality controller will take samples and carry out tests see if they are compliant.

You will establish your own quality control measures such as checking for the moisture content, density or melt flow rate.

Then, the materials are stored awaiting production.

Before production begins, the raw materials have to be prepared.

NOTE:

If your using PVC material to manufacture corrugated pipes, there are two preparation processes you will perform on PVC.

First, we have mixing the PVC (thermoplastic material) with other additives.

Second, you need to heat the PVC resin to remove any moisture it contains –then rapidly cool it to prevent early plasticization.

The equipment to perform these processes is the hot and cool mixer used for preparing PVC resin.

In the hot tank, the PVC resin with other additives is heated to over 100oc and agitated by a stainless steel blade.

The material mix is then discharged into the cooling tank, which cools it quickly to prevent early plastization or decay.

From the cooling tank, you will discharge the materials into a spring loader.

It loads the material into the hopper of the extruder.

While product mixtures vary depending on the manufacturer, it’s common practise to include carbon black, which is a UV inhibitor and pigment.

Carbon black is used for sewer and above ground uses of corrugated pipes.

On the other hand, the yellow pigment is used for pipes used in natural gas production.

Extrusion by two single-screw extruders (co-extrusion)

Extrusion involves softening the thermoplastic material.

This softening is what we call plasticization.

The equipment used to perform plasticization is called the extruder.

NOTE:

You may use the following thermoplastic materials

PVC

HDPE

PP

When we make PVC corrugated pipes, we need to use the conical twin screw extruder.

More details please contact Ellen Liu or Xiaoyan.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews