HDPE PP Double Wall Corrugated Pipe Production Line Single Extruder For Sewage

Product Description

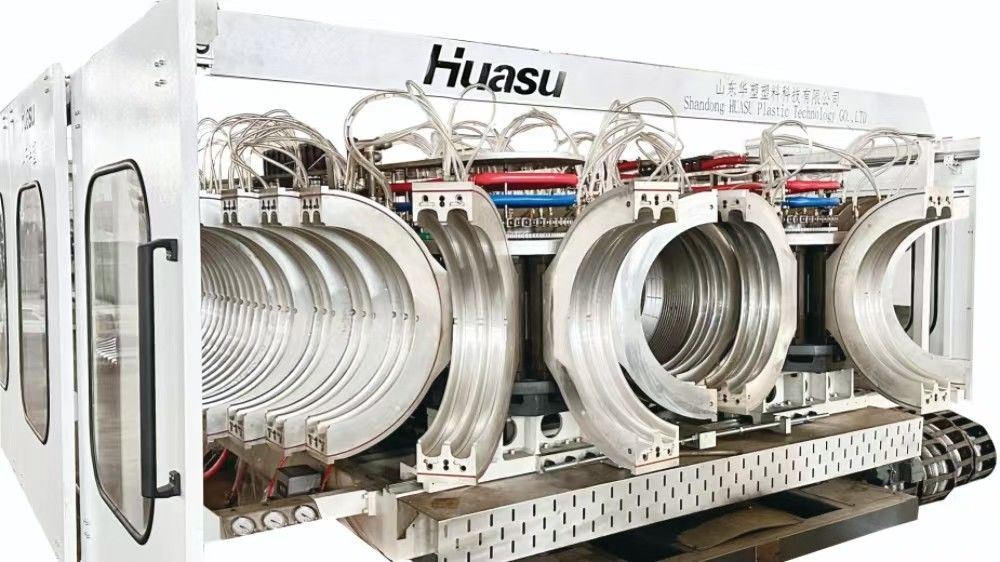

The molds adopt the double flow channel structure and nitriding polishing processed die head. This makes the adjustment of partial wall convenient and fast and ensures the thickness of the inner and outer wall uniform and stable.

The latest design of closed pressure water cooling structure, full cooling, multi-point distribution vacuum system, higher efficiency, faster production speed.

Online double wall belling function and automatic lubrication system

The advanced shuttle structure and reasonable track design make the module run more smoothly and the forming section longer, which is conducive to rapid production. lower energy consumption and cost saving.

It’s simple and fast to replace the mold, saving time and cost

Online EPS uninterruptible power supply ensures the automatic return of the forming worktable in case of sudden power failure, so that the mould block can be separated from the water sleeve in time.

Siemens professional PLC programming control cutting machine, double knife cutting, simple and sensitive operation, accurate, stable and reliable.

Human machine interface, extrusion synchronous control system, with remote communication function and realize remote fault diagnosis and troubleshooting.

Product Advantage

The screw which are specially customized for corrugated pipe products, using 38CrMoAIA material, spraying bimetal alloy layer and nitriding treatment, which greatly improves the service life of screw.

The control system uses a full set of Siemens PLC control system with low-voltage electrical components to ensure the continuous and smooth operation of equipment.

For corrugated pipe belling molding process, we adopt integrated design of process parameters to achieve fixed corrugated pipe belling process data, along with deceleration and synchronization for extruder and forming machine. Thereby it can reduce the start-up scrap rate and operator's operating difficulty.

Product Parameter

|

SBG180 |

SBG260 |

SBG300 |

SBG600 |

SBG800 |

SBG1000 |

SBG1200 |

SBG1500 |

| Max. pipe ID |

180 |

260 |

300 |

600 |

800 |

1000 |

1200 |

1500 |

| Min. pipe ID |

32 |

90 |

100 |

200 |

200 |

400 |

600 |

600 |

| Total power(kw) |

225 |

340 |

360 |

498 |

730 |

800 |

880 |

970 |

| No of mold block |

28/36 |

28/36 |

36 |

36 |

36 |

38 |

38 |

42 |

| Colling method |

Water |

Water |

Water |

Water |

Water |

Water |

Water |

Water |

| Extruder model |

SJ65/33 |

SJ75/33 |

SJ75/33 |

SJ90/33 |

SJ90/33 |

SJ90/33 |

SJ90/36 |

SJ90/36 |

| SJ75/33 |

SJ90/33 |

SJ90/33 |

SJ120/33 |

SJ120/33 |

SJ120/33 |

SJ120/36 |

SJ150/36 |

Application

This line is widely used in municipal engineering, underground sewage pipe of residential area, sewage discharge and other fields.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews