Product Description:

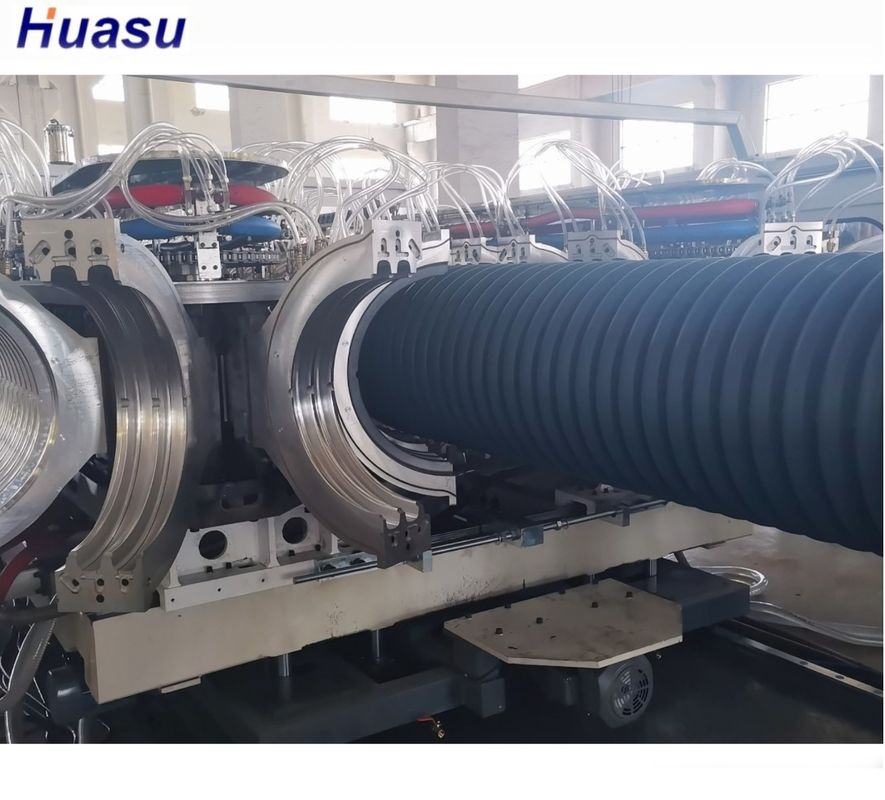

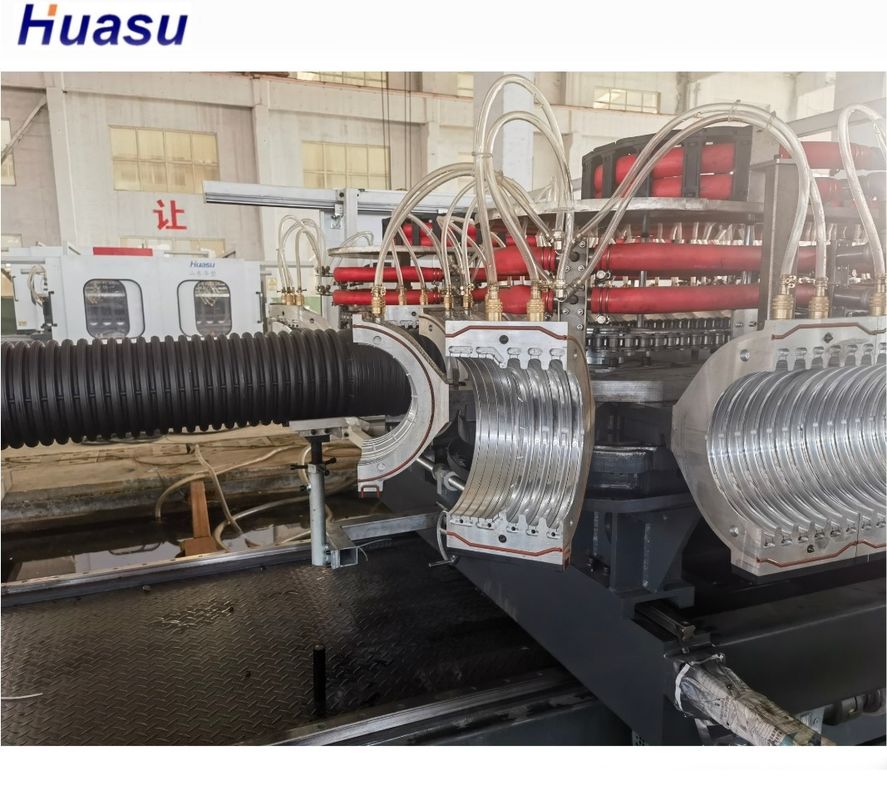

Our high speed double wall corrugated pipe extrusion line, from ID thirty two millimeter to one thousand five hundred millimeter. The molds adopt the double flow channel structure and nitriding polishing processed die head. This makes the adjustment of partial wall convenient and fast and ensures the thickness of the inner and outer wall uniform and stable.

The latest design of closed pressure water cooling structure, full cooling, multi-point distribution vacuum system, higher efficiency, faster production speed.

And also with online double wall belling function and automatic lubrication system

The advanced shuttle structure and reasonable track design make the module run more smoothly and the forming section longer, which is conducive to rapid production. lower energy consumption andcost saving. It's simple and fast to replace the mold, saving time and cost

Online EPS uninterruptible power supply ensures the automatic return of the forming worktable incase of sudden power failure, so that the mould block can be separated from the water sleeve in time. Siemens professional PLC programming control cutting machine, double knife cutting, simple andsensitive operation, accurate, stable and reliable.

Human machine interface, extrusion synchronous control system, with remote communication function and realize remote fault diagnosis and trouble shooting

This line is widely used in municipal engineering, underground sewage pipe of residential area,sewage discharge and other fields.

Technical Parameters:

| Type |

SBG-180H |

SBG-260H |

SBG-300H |

SBG-600H |

SBG-800H |

SBG-1000H |

SBG-1200H |

SBG-1600H |

| ID(mm) |

Φ32-180 |

Φ90-260 |

Φ100-300 |

Φ200-600 |

Φ200-800 |

Φ400-1000 |

Φ600-1200 |

Φ600-1500 |

| Energy Consumption (kw) |

260 |

315 |

360 |

498 |

730 |

800 |

880 |

970 |

Applications:

- Underground Drainage Systems: The durable and reliable pipes produced by this machine are perfect for use in underground drainage systems, ensuring proper water flow and management.

- Cable Protection: The double wall corrugated pipes manufactured by this equipment are ideal for protecting cables from external elements, making them suitable for various industries.

- Agricultural Irrigation: These pipes can be used in agricultural irrigation systems, providing a cost-effective and efficient solution for water distribution.

- Infrastructure Development: The high-quality pipes produced by this production line are essential for infrastructure development projects, such as road construction and sewage systems.

Whether you are looking to enhance your underground drainage systems, protect cables, facilitate agricultural irrigation, or contribute to infrastructure development, the HUASU SBG Double Wall Corrugated Pipe Extrusion Line offers the reliability and performance you need. Trust in this top-of-the-line equipment for all your double wall corrugated pipe manufacturing needs.

Customization:

Customize your double wall corrugated pipe extrusion line with the HUASU SBG model. Originating from China, this production line features 20CrMnTi gear material and a double-screw design for high-speed production. Enjoy the advantages of a PLC control system and the assurance of a new condition. Upgrade your manufacturing capabilities with our high-speed DWCP production line for sale, offering top-of-the-line China corrugated pipe manufacturing equipment.

Support and Services:

The Double Wall Corrugated Pipe Extrusion Line product provides comprehensive technical support and services to ensure optimal performance and efficiency. Our team of experts is available to assist with installation, maintenance, and troubleshooting to address any issues that may arise. Additionally, we offer training programs to help users maximize the capabilities of the extrusion line and achieve the best results.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews