Product Description:

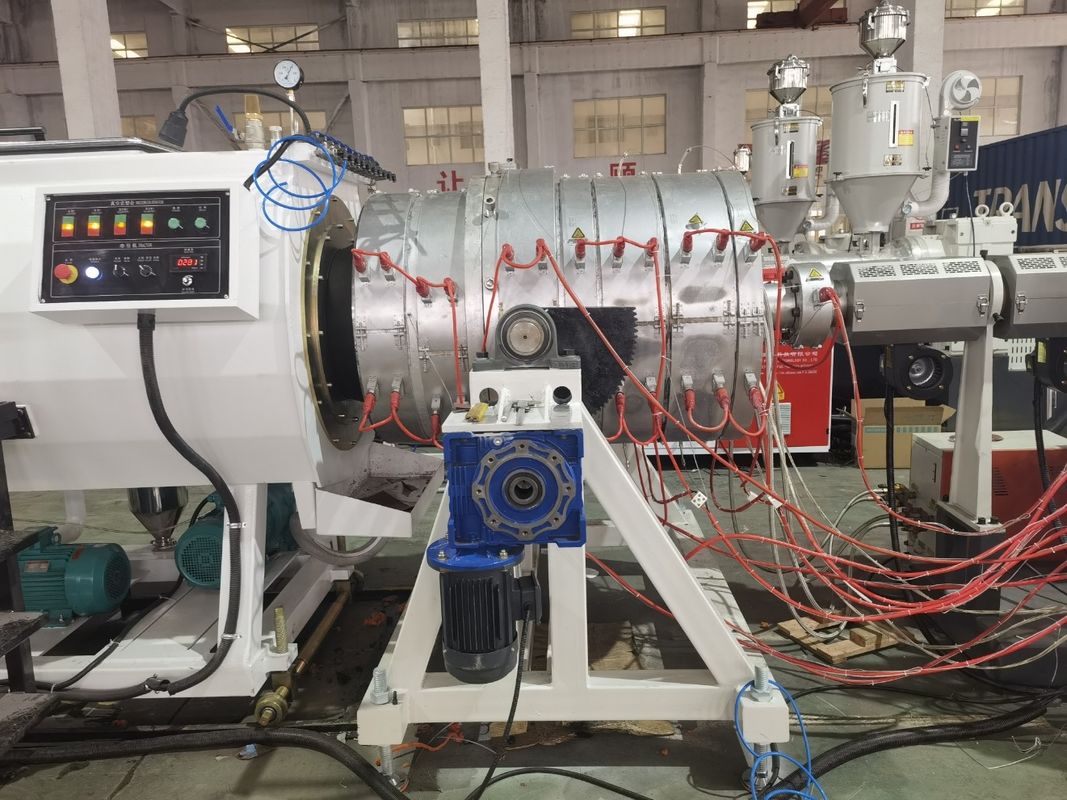

The HDPE Pipe Extrusion Line is a versatile and efficient machine designed to produce high-quality HDPE pipes for various applications. Whether you need HDPE Solid Wall Pipe, HDPE Drainage Pipes, or other types of pipes, this extrusion line can meet your production needs.

With the ability to process a variety of materials including PE, PP, HDPE, and PVC, this machine offers flexibility and versatility in manufacturing different types of pipes. The extrusion line operates on a voltage of 380V/50Hz, making it suitable for use in a wide range of industrial settings.

One of the key features of the HDPE Pipe Extrusion Line is its customizable screw configuration. You can choose between a Single Screw or Double Screw design based on your specific production requirements. This flexibility allows you to optimize the extrusion process for different types of pipes and materials.

The core components of the extrusion line include a high-quality motor, PLC system, and gearbox. The motor is sourced from reputable brands such as Siemens Beide or WEG, ensuring reliable performance and durability. The PLC system provides precise control over the extrusion process, while the gearbox facilitates smooth operation and consistent output quality.

Whether you are producing HDPE Solid Wall Pipe for water supply systems, HDPE Drainage Pipes for wastewater management, or other types of pipes for industrial applications, the HDPE Pipe Extrusion Line offers a cost-effective and efficient solution. With its advanced technology and robust construction, this machine is designed to deliver consistent and high-quality pipes with minimal downtime.

Investing in the HDPE Pipe Extrusion Line can help you streamline your production process, increase efficiency, and meet the growing demand for high-quality pipes in the market. Whether you are a small-scale manufacturer or a large industrial facility, this extrusion line is designed to meet your specific needs and deliver reliable performance for years to come.

Features:

- Product Name: HDPE Pipe Extrusion Line

- Core Components: Motor, PLC, Gearbox

- Motor: Siemens Beide/WEG

- Voltage: 380V/50Hz

- Processing Material: PE PP HDPE PVC

- Temperature Control: Omron, Siemens

Technical Parameters:

| Screw No |

Single Or Double Screw |

| Core Components |

Motor, PLC, Gearbox |

| Crusher And Miller |

Available For Choosing |

| Voltage |

380V/50Hz |

| Screw Type |

Single Screw |

| Motor |

Siemens Beide/WEG |

| Temperature Control |

Omron, Siemens |

| Processing Material |

PE PP HDPE PVC |

Applications:

With temperature control systems from Omron and Siemens, the HDPE Pipe Extrusion Line ensures precise and consistent production processes, resulting in high-quality pipes with excellent physical properties. Whether you need single or double screw configuration, this extrusion line can be tailored to your specific requirements, providing flexibility and versatility in production.

The motor options of Siemens Beide or WEG guarantee efficient operation and long-term durability for the extrusion line. Operating at a voltage of 380V/50Hz, this machine is suitable for a wide range of manufacturing environments, ensuring consistent and reliable performance.

Equipped with core components such as motor, PLC, and gearbox, the Huasu HDPE Pipe Extrusion Line offers a complete solution for HDPE pipe production. From raw material feeding to final pipe cutting, this extrusion line streamlines the entire production process, maximizing efficiency and productivity.

The Product Application Occasions and Scenarios for the HDPE Pipe Extrusion Line are diverse and extensive. Whether you are producing HDPE Solid Wall Pipes for water supply, sewage systems, or industrial applications, this extrusion line can meet your specific production needs. Its robust construction and advanced technology make it suitable for both small-scale and large-scale pipe manufacturing operations.

In conclusion, the Huasu HDPE Pipe Extrusion Line is a reliable and efficient solution for producing high-quality HDPE pipes. With its advanced features, durable components, and precise control systems, this extrusion machine is ideal for a wide range of applications in the plastic pipe industry.

Customization:

Product Customization Services for the HDPE Pipe Extrusion Line:

- Brand Name: Huasu

- Place Of Origin: China

- Motor: Siemens Beide/WEG

- Screw No: Single Or Double Screw

- Screw Type: Single Screw

- Core Components: Motor, PLC, Gearbox

- Temperature Control: Omron, Siemens

Please contact with me for more details:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews