PE PP Pipe Material Double Wall Corrugated Pipe Extrusion Line with Siemens Main Electrical Parts:

Product Description:

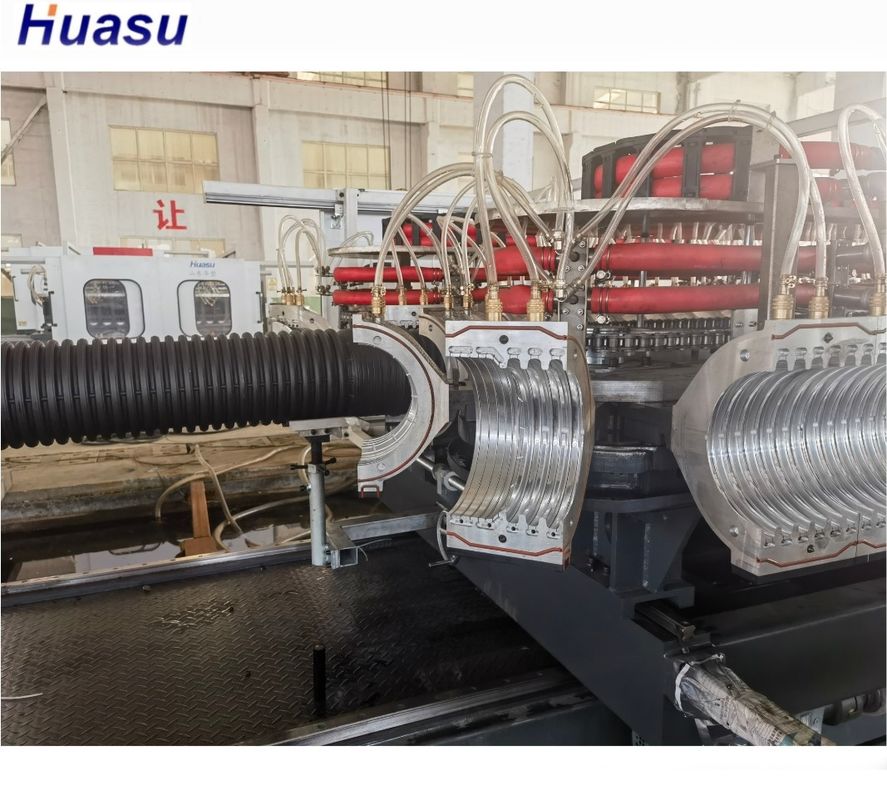

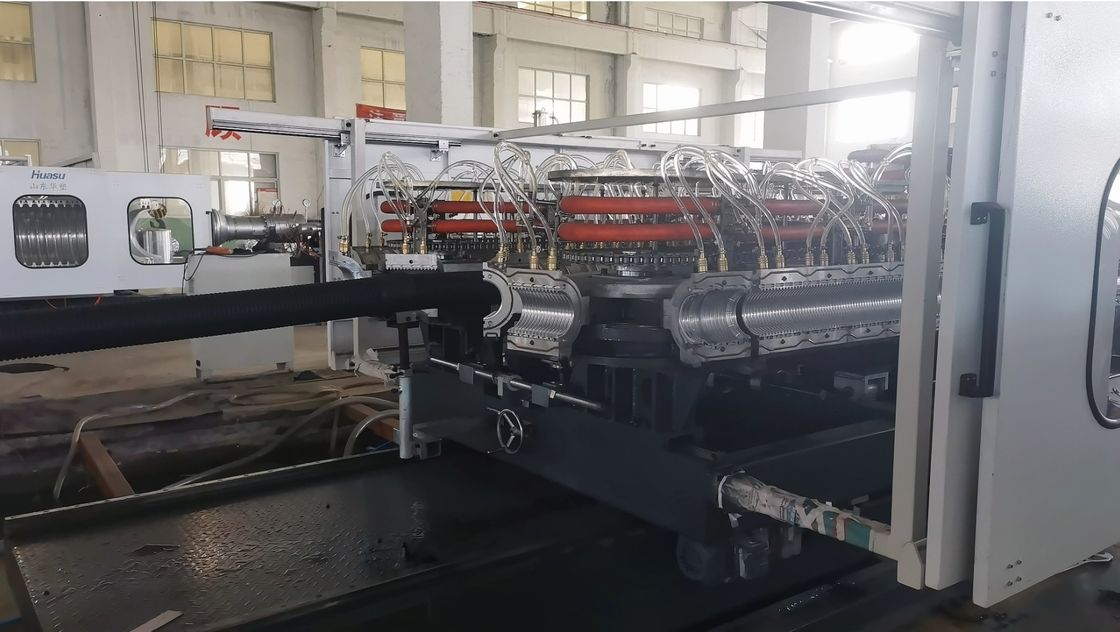

The Double Wall Corrugated Pipe Extrusion Line is a top-of-the-line solution for producing high-quality double wall corrugated pipes. This advanced machine is equipped with a single-screw extruder, ensuring efficient and precise production of double wall corrugated pipes.

With a single-screw extruder as the core component, this corrugated pipe making machine offers reliable performance and consistent output. The extruder is designed to handle a wide range of materials and is capable of producing pipes with diameters ranging from small to large sizes.

For optimal cooling and shaping of the pipes, the Double Wall Corrugated Pipe Extrusion Line comes with a water tank included in the package. This water tank is essential for maintaining the quality and integrity of the pipes during the extrusion process.

One of the key features of this extrusion line is its customization options. Customers can request specific modifications and configurations to tailor the machine to their unique production requirements. This level of customization ensures that the machine meets the exact needs of the user, resulting in enhanced efficiency and productivity.

Designed as a Single Screw Extruder, this Double Wall Corrugated Pipe Production Solutions machine offers a reliable and straightforward operation. The single-screw design simplifies the extrusion process, making it easier to control and adjust various parameters to achieve the desired pipe specifications.

With an Extruder Capacity ranging from 250kg/h to 1000kg/h, this Double Wall Corrugated Pipe Extrusion Machine is suitable for both small-scale and large-scale production needs. Whether producing pipes for residential drainage systems or industrial applications, this extrusion line can meet the demands of various projects.

In conclusion, the Double Wall Corrugated Pipe Extrusion Line is a versatile and efficient solution for manufacturers looking to produce high-quality double wall corrugated pipes. With its single-screw extruder, water tank, customizable options, and reliable performance, this machine offers a comprehensive solution for all corrugated pipe production needs.

Technical Parameters:

| Customized |

Customized |

| Extruder Capacity |

250-1000kg/h |

| Pipe Material |

PE, PP, PVC |

| Water Tank |

1 Set |

| Moulds Number |

36/38 Pairs |

| Main Electrical Parts |

Siemens Brand |

| Pipe Range |

ID100-ID1500mm |

| Screw |

Single-Screw |

| Barrel Screw |

Hardness Of Screw HV>740 |

| Extruder Type |

Single Screw Extruder |

Applications:

When it comes to the production of double wall corrugated pipes, the HUASU SBG Double Wall Corrugated Pipe Extrusion Line from China is the ideal solution. This advanced equipment is designed to meet the demands of various industries requiring high-quality corrugated pipes.

The HUASU SBG extrusion line is perfect for manufacturing double wall corrugated pipes using materials such as PE, PP, and PVC. With a single-screw extruder and an extruder capacity ranging from 250-1000kg/h, this equipment ensures efficient and precise production of corrugated pipes.

Whether you are in the construction, telecommunications, or agricultural sector, the HUASU SBG extrusion line is suitable for a wide range of applications. Its reliable performance and certification with ISO and CE standards guarantee superior quality output.

With a minimum order quantity of just 1 set and a price range of US$50,000-5,000,000, this equipment offers flexibility and cost-effectiveness. The standard packaging and delivery time of 30-90 days ensure a smooth and convenient purchasing process.

Payment terms such as TT and L/C make it easy to acquire the HUASU SBG extrusion line, while a supply ability of 100 lines ensures availability for your production needs. The set includes a single-screw extruder, water tank, and all the necessary components for efficient double wall corrugated pipe production.

In conclusion, the HUASU SBG Double Wall Corrugated Pipe Extrusion Line is the perfect solution for industries requiring advanced corrugated pipe production technology and equipment. Whether you need a corrugated pipe forming machine or double wall corrugated pipe equipment, this product from China is the ultimate choice.

Customization:

Our Double Wall Corrugated Pipe Extrusion Line, customized by HUASU, model SBG, is manufactured in China with certifications in ISO and CE standards. The minimum order quantity is 1 SET, priced at US$50,000-5,000,000, and packaged in a standard package for delivery within 30-90 days. Payment terms include TT and L/C, with a supply ability of 100 lines. The pipe range is from ID100 to ID1500mm, suitable for pipe materials such as PE, PP, and PVC. With 23 years of production experience, our corrugated pipe machinery is fully customized to meet your specific requirements. The extruder type is a Single Screw Extruder, ensuring high-quality production of Double Wall Corrugated Pipe Equipment for your corrugation pipe machine needs.

Please contact with me for more details:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews