HDPE Pipe Extrusion Line with 38CrMoAl Screw Material and Water Cooling Method:

Product Description:

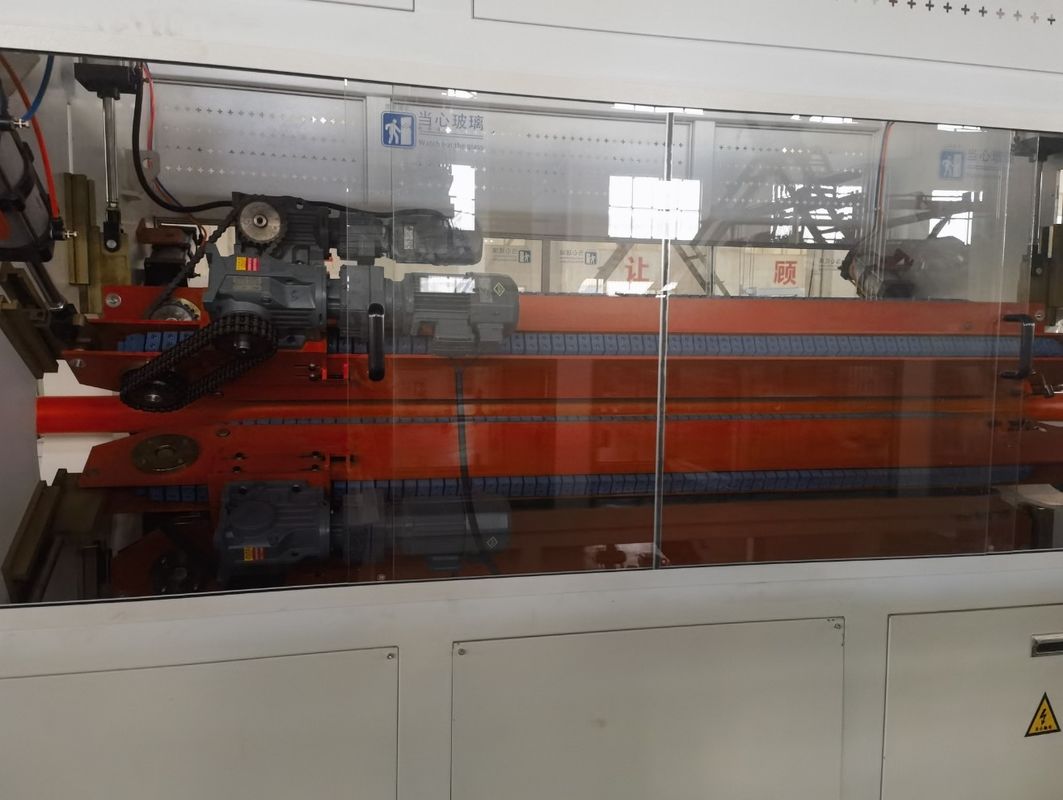

Controlled by a sophisticated PLC system, this HDPE Pipe Extrusion Machine offers unparalleled control and monitoring capabilities. The PLC control system allows operators to easily adjust and optimize various parameters to meet specific production requirements, ensuring consistent and accurate results.

Constructed from durable and corrosion-resistant High-Density Polyethylene (HDPE) material, the extrusion line is built to withstand the demands of continuous operation and deliver long-lasting performance. HDPE is known for its exceptional strength, flexibility, and resistance to chemicals and abrasion, making it an ideal choice for producing high-quality drainage pipes.

The cooling method employed in this extrusion line is water cooling, which effectively dissipates heat generated during the extrusion process. The efficient cooling system helps maintain optimal operating temperatures, allowing for continuous and uninterrupted production of HDPE pipes with precise dimensions and excellent surface finish.

Equipped with a high-performance Siemens inverter, the HDPE Pipe Extrusion Line ensures smooth and efficient operation, with the ability to adjust the speed and torque of the extruder motor as needed. The Siemens inverter provides reliable control over the extrusion process, enhancing overall productivity and quality of the finished pipes.

Manufactured in Qingdao, China, a hub of industrial innovation and manufacturing excellence, this HDPE Pipe Extrusion Line benefits from the expertise and craftsmanship of skilled engineers and technicians. The machine is designed and built to meet international quality standards, offering exceptional performance and reliability for a wide range of extrusion applications.

Whether you are producing HDPE drainage pipes for residential, commercial, or industrial applications, this extrusion line is a reliable and efficient solution for meeting your production needs. With its advanced features, robust construction, and precise control capabilities, the HDPE Pipe Extrusion Line is designed to deliver superior performance and consistency in producing high-quality pipes.

Technical Parameters:

| Model |

Single Screw Extruder |

| Automation Grade |

High Automation |

| Cooling Method |

Water Cooling |

| Material |

High-Density Polyethylene |

| Inverter |

Siemens |

| Screw Material |

38CrMoAl |

| Screw No |

Single-screw |

| Electric Parts |

Siemens |

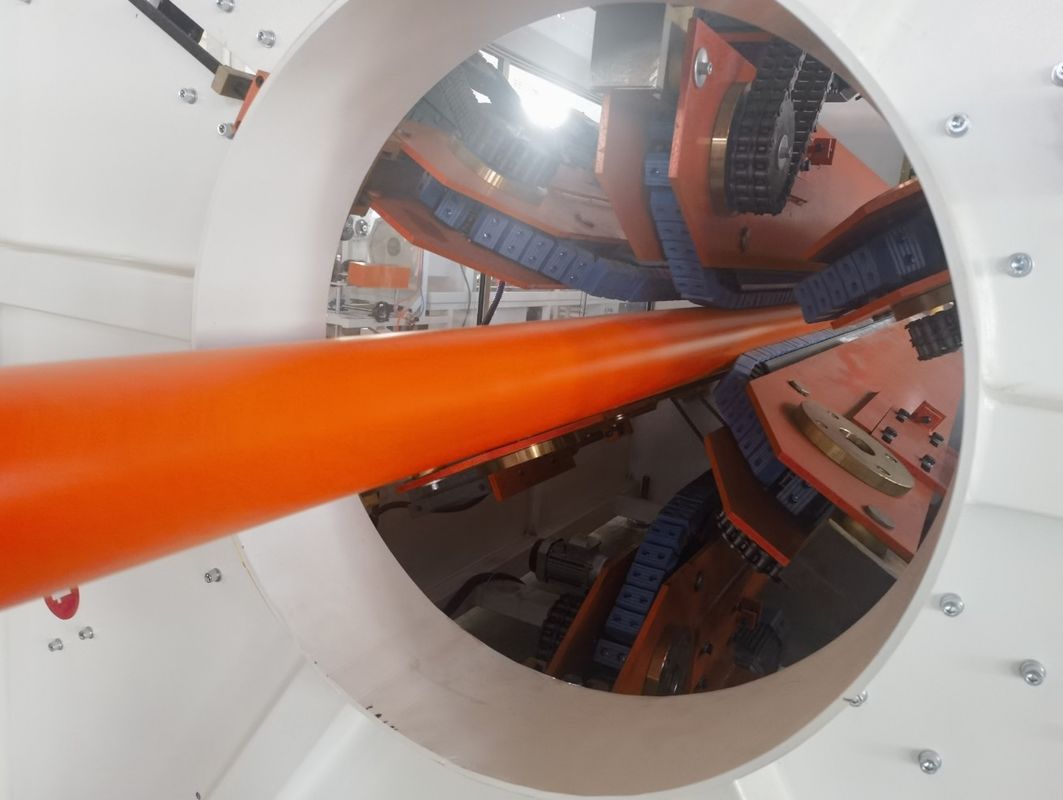

| Cutting Machine |

Planetary Cutting Machine |

| Control |

PLC |

Applications:

The Huasu HDPE Pipe Extrusion Line is a cutting-edge extrusion machine designed for the production of high-quality HDPE Drainage Pipes. Manufactured in China, this extrusion line is known for its high automation grade, making it a preferred choice for industrial applications.

Equipped with a Single Screw Extruder model, the Huasu HDPE Pipe Extrusion Line ensures efficient and precise extrusion of HDPE materials, resulting in durable and reliable drainage pipes. The PLC control system further enhances the automation level, providing seamless operation and precise control over the production process.

One of the key features of the Huasu HDPE Pipe Extrusion Line is its water cooling method, which helps maintain optimal temperature levels during the extrusion process. This not only improves the overall quality of the HDPE drainage pipes but also increases the productivity of the extrusion line.

The Huasu HDPE Pipe Extrusion Line is ideal for a wide range of applications and scenarios, including industrial drainage systems, municipal water supply projects, agricultural irrigation networks, and more. Its high automation grade and advanced control system make it suitable for large-scale production environments where efficiency and precision are paramount.

Whether you are looking to manufacture HDPE drainage pipes for commercial or residential use, the Huasu HDPE Pipe Extrusion Line offers the reliability, performance, and precision required for producing top-quality products. Invest in this extrusion line to streamline your production process and meet the growing demand for high-quality HDPE drainage pipes in various applications.

Customization:

Product Customization Services for HDPE Pipe Extrusion Line:

Brand Name: Huasu

Place Of Origin: China

Inverter: Siemens

Origin: Qingdao China

Screw No: Single-screw

Screw Material: 38CrMoAl

Automation Grade: High Automation

Please contact with me for more details:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews