Precise Double Wall Corrugated Pipe Extrusion Line with Siemens Contactor and Automatic Operation:

Product Description:

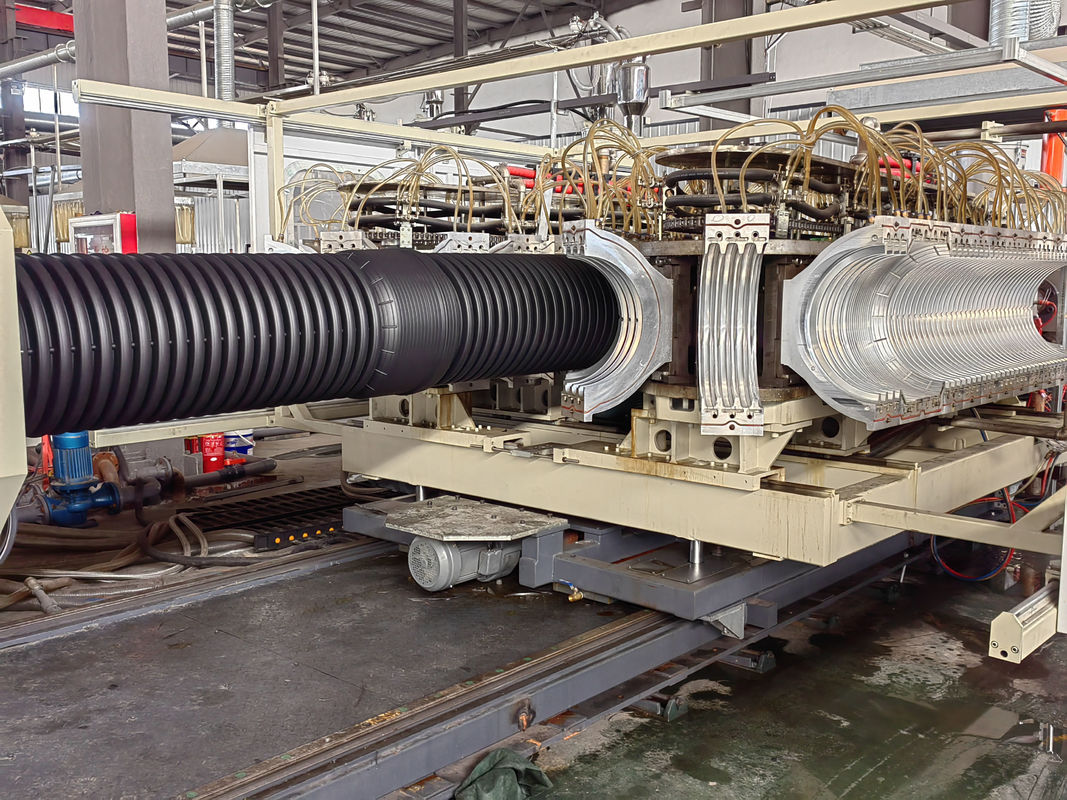

The Double Wall Corrugated Pipe Extrusion Line is a state-of-the-art system designed for the efficient production of double wall corrugated pipes. This production line is ideal for manufacturers looking to produce high-quality double wall corrugated pipes made from PE plastic.

With its automatic automation system, this double wall corrugated pipe production line offers a streamlined and hassle-free operation. The automation ensures consistent production quality and reduces the need for manual intervention, making it a cost-effective solution for manufacturers.

The color customization option allows customers to choose the color of the double wall corrugated pipes according to their specific requirements. Whether it is for branding purposes or project specifications, the color can be tailored to meet the desired aesthetic.

When it comes to raw materials, the Double Wall Corrugated Pipe Extrusion Line is compatible with a range of materials including PP, PE, and PVC. This flexibility in raw material options provides manufacturers with the versatility to produce pipes with different material properties based on their application needs.

With a production capacity ranging from 100 to 2000 Kg/h, this Corrugated Pipe Production System is suitable for both small-scale and large-scale production requirements. Whether it is for a small workshop or a large manufacturing facility, this production line can cater to a wide range of production volumes.

The Double Wall Corrugated Pipe Extrusion Line comes equipped with a Double Wall Corrugated Pipe Mould, which is essential for shaping the pipes into the desired double wall corrugated profile. The precision-engineered mould ensures the accurate and consistent formation of the pipes, meeting the required specifications with each production run.

Technical Parameters:

| Color |

As To Customer's Request |

| Automation |

Automatic |

| Screw Channel Structure |

Deep Screw |

| Contactor |

Siemens,Schnerder |

| Raw Material |

PP/PE/PVC |

| Pipe Diameter |

32-1500mm |

| Electric |

Siemens |

| Screw Material |

38CrMoALA |

| Plastic Processed |

PE |

| Capacity |

100-2000Kg/h |

Applications:

When considering the Product Application Occasions and Scenarios for the Double Wall Corrugated Pipe Extrusion Line by HUASU (model SBG), there are various industries and projects where this product excels.

One key application scenario is in the production of sewage pipes. The double wall corrugated pipe mould used in this extrusion line ensures high-quality and durable sewage pipes that are essential for efficient waste management systems in urban and rural areas. Municipalities, construction companies, and infrastructure development projects can benefit greatly from this sewage pipe machine.

Another significant application occasion is in the manufacturing of corrugation pipes for various purposes such as cable protection, drainage systems, and underground conduit systems. The SBG extrusion line, with its automatic grade and Siemens electric components, is capable of producing corrugation pipes with precision and consistency.

This product, originating from China and holding ISO and CE certifications, has a minimum order quantity of 1 set and a price range of US$50,000 to US$5,000,000. The standard packaging details, along with a delivery time of 30-90 days, make it convenient for buyers to receive their orders promptly.

With payment terms including TT and L/C, customers have flexible options to complete their transactions. The supply ability of 100 lines ensures that the demand for this double wall corrugated pipe extrusion line can be met efficiently.

Moreover, the color customization option allows customers to tailor the machine to their preferences, while the use of PE plastic processed material ensures the durability and longevity of the pipes produced.

Equipped with Siemens and Schnerder contactors, the SBG extrusion line by HUASU is a reliable and high-performance solution for industries requiring double wall corrugated pipes for various applications.

Customization:

Our Product Customization Services for the Double Wall Corrugated Pipe Extrusion Line include:

- Brand Name: HUASU

- Model Number: SBG

- Place Of Origin: China

- Certification: ISO, CE

- Minimum Order Quantity: 1 SET

- Price: US$50,000-5,000,000

- Packaging Details: Standard Package

- Delivery Time: 30-90 Days

- Payment Terms: TT, L/C

- Supply Ability: 100 Line

- Screw Material: 38CrMoALA

- Plastic Processed: PE

- Capacity: 100-2000 Kg/h

- Automation: Automatic

- Raw Material: PP/PE/PVC

Our customization services cater to your specific needs for Corrugated Pipe Manufacturing Machinery, Double Wall Corrugated Pipe Production Solutions.

Please contact with me for more details:

Sandy Liu

Shandong Huasu Plastic Technology Co., Ltd.

WhatsApp: +86 13864817239

Wechat: +86 1386481739

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews