PE Double Wall Corrugated Pipe Extrusion Line with Pipe Diameter 32-1500mm Wide Range of Applications:

Product Description:

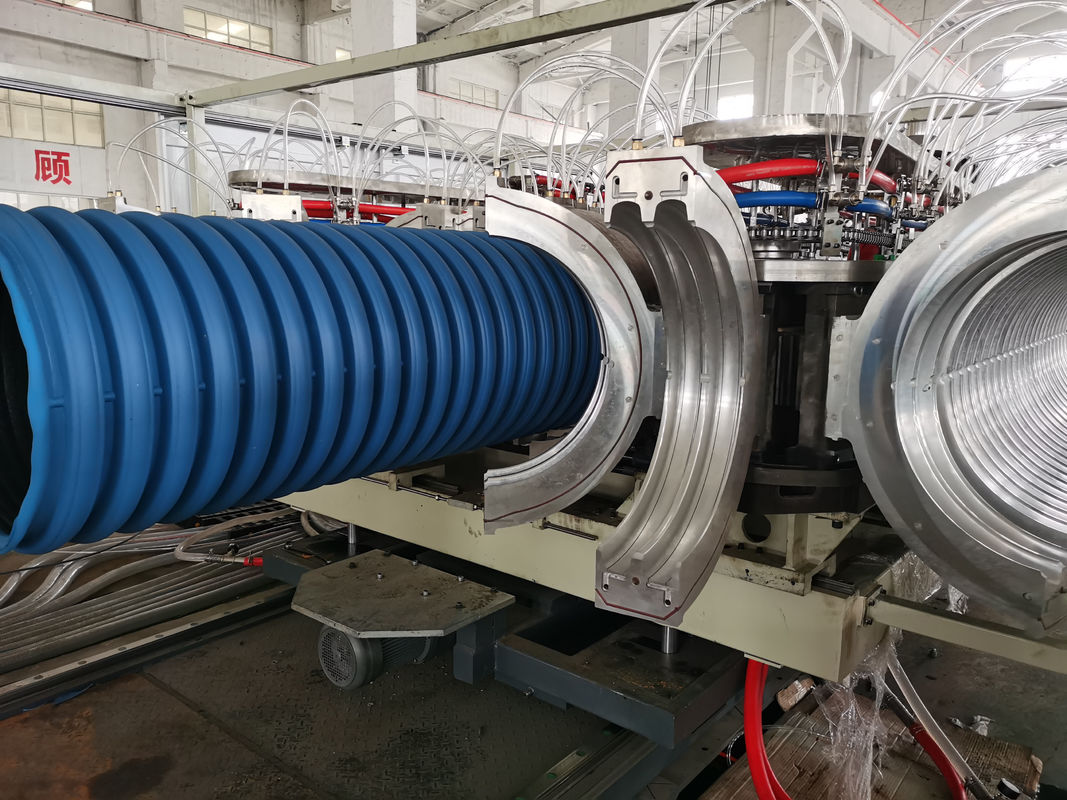

The Double Wall Corrugated Pipe Extrusion Line is a high-quality plastic pipe manufacturing equipment designed for producing double wall corrugated pipes with precision and efficiency. This cutting-edge machine is ideal for manufacturers looking for reliable Double Wall Corrugated Pipe Production Solutions for various applications such as sewage systems, drainage systems, and cable protection.

Powered by advanced technology and innovative features, this extrusion line is specifically engineered to process PE plastic, making it suitable for a wide range of projects requiring durable and flexible pipes. The screw material used in this machine is 38CrMoALA, known for its high strength and resistance to wear, ensuring long-lasting performance and consistent output.

With an Automatic Grade system, this Double Wall Corrugated Pipe Extrusion Line offers automated operation for increased efficiency and productivity. The Automatic Grade feature allows for easy monitoring and control of the production process, reducing the need for manual intervention and minimizing the risk of errors.

The Screw Channel Structure of this extrusion line is designed with a Deep Screw configuration, which enhances the mixing and melting of the raw materials, resulting in uniform and high-quality pipes. The Deep Screw design ensures optimal plasticization and homogenization of the PP, PE, and PVC raw materials, leading to superior pipe performance and durability.

Manufacturers in the plastic pipe industry can benefit greatly from the versatility and reliability of this Double Wall Corrugated Pipe Extrusion Line. Whether producing sewage pipes, drainage pipes, or cable protection pipes, this machine offers a cost-effective solution for meeting the demands of various applications.

Overall, the Double Wall Corrugated Pipe Extrusion Line is a top-of-the-line equipment that delivers exceptional performance, precision, and efficiency in plastic pipe manufacturing. With its focus on quality, durability, and automation, this machine is a valuable asset for companies looking to streamline their production processes and deliver high-quality double wall corrugated pipes for diverse projects.

Technical Parameters:

| Pipe Diameter |

32-1500mm |

| Automatic Grade |

Automatic |

| Plastic Processed |

PE |

| Raw Material |

PP/PE/PVC |

| Screw Material |

38CrMoALA |

| Color |

As To Customer's Request |

| Contactor |

Siemens, Schnerder |

| Capacity |

100-2000Kg/h |

| Automation |

Automatic |

| Electric |

Siemens |

Applications:

When considering the application occasions and scenarios for the HUASU SBG Double Wall Corrugated Pipe Extrusion Line, it becomes evident that this product is a versatile and essential piece of Corrugated Pipe Manufacturing Machinery. With its automated features and efficient design, the Double Wall Corrugated Pipe Extrusion Line is well-suited for a variety of settings and industries.

Manufacturers looking to establish or expand their production of Double Wall Corrugated Pipes will find the SBG Extrusion Line to be a valuable addition to their facilities. The automated nature of this Corrugated Pipe Production System allows for increased productivity and consistency in output, making it ideal for high-volume production needs.

Whether used in drainage systems, cable protection, or other infrastructure projects, the HUASU SBG Extrusion Line from China is a reliable choice. Its Certification in ISO and CE ensures quality and compliance with international standards, giving buyers peace of mind regarding the product's performance and safety.

With a wide range of Pipe Diameter options from 32mm to 1500mm, customers can tailor their production capabilities to meet specific project requirements. The use of PP, PE, or PVC as Raw Materials allows for flexibility in material selection, while the Deep Screw Channel Structure ensures efficient extrusion and shaping of the corrugated pipes.

Available at a competitive price range of US$50,000 to 5,000,000, with a Minimum Order Quantity of 1 SET, the HUASU SBG Extrusion Line offers excellent value for money. The Packaging Details are standard, and Delivery Time ranges from 30 to 90 days, making it a convenient and timely solution for manufacturers.

Payment Terms such as TT and L/C are accepted, and the Supply Ability of 100 lines ensures that customers can obtain the necessary equipment to meet their production demands. The color customization option allows for personalization based on customer preferences, further enhancing the appeal of this Automated Double Wall Corrugated Pipe Production Line.

Customization:

Product Customization Services for the Double Wall Corrugated Pipe Extrusion Line:

Brand Name: HUASU

Model Number: SBG

Place Of Origin: China

Certification: ISO, CE

Minimum Order Quantity: 1 SET

Price: US$50,000-5,000,000

Packaging Details: Standard Package

Delivery Time: 30-90 Days

Payment Terms: TT, L/C

Supply Ability: 100 Line

Automatic Grade: Automatic

Pipe Diameter: 32-1500mm

Color: As To Customer's Request

Screw Channel Structure: Deep Screw

Contactor: Siemens, Schnerder

Please contact with me for more details:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews