Double Wall Corrugated Pipe Extrusion Line with Deep Screw Channel Structure

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Plc | Siemens | Outside Diameter | 40mm-1600mm |

|---|---|---|---|

| Screw And Barrel | 38crmoaia | Max Pipe Diameter | 1600mm |

| Forming Machine | 1 Set | Inverter | Siemens |

| Specification | 32*1500mm | Customized | Customized |

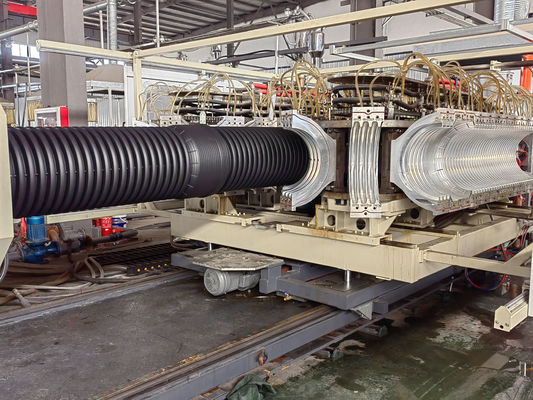

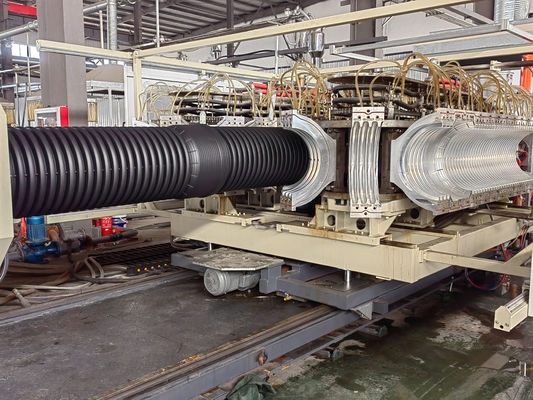

Double Wall Corrugated Pipe Extrusion Line with Deep Screw Channel Structure:

Product Description:

The Double Wall Corrugated Pipe Extrusion Line is a state-of-the-art machine designed for the efficient production of high-quality double wall corrugated pipes. This advanced extrusion line incorporates cutting-edge technology and premium components to ensure reliable performance and superior results.

Equipped with a PLC system from Siemens, the Double Wall Corrugated Pipe Extrusion Line offers precise control and monitoring capabilities, contributing to enhanced productivity and operational efficiency. The Siemens PLC enables seamless integration of various process parameters, facilitating smooth operation and optimal output.

The extrusion line includes a single set corrugator, specially designed for the production of double wall corrugated pipes. This high-performance corrugator ensures consistent and uniform corrugation of the pipes, resulting in excellent structural integrity and durability. With the ability to accommodate a maximum pipe diameter of 1600mm, this machine is ideal for manufacturing a wide range of pipe sizes to meet diverse industry requirements.

Featuring a forming machine, the Double Wall Corrugated Pipe Extrusion Line enables the precise shaping and sizing of the pipes with exceptional accuracy. The forming machine plays a crucial role in maintaining the desired dimensions and quality of the pipes throughout the production process, ensuring consistent performance and product reliability.

One of the key highlights of this extrusion line is the barrel nitriding depth, ranging from 0.4mm to 0.7mm. This optimized nitriding depth enhances the durability and wear resistance of the extruder barrel, prolonging its lifespan and reducing maintenance requirements. The superior nitriding treatment contributes to the overall robustness and longevity of the machine, making it a reliable investment for long-term production needs.

In addition to the high-quality components and advanced features, the Double Wall Corrugated Pipe Extrusion Line is designed to accommodate the production of various types of double wall corrugated pipes with precision and efficiency. Whether for drainage systems, cable protection, or other applications, this machine offers versatility and flexibility to meet diverse manufacturing demands.

Overall, the Double Wall Corrugated Pipe Extrusion Line stands out as a top-of-the-line solution for manufacturers seeking a reliable and high-performance machine for producing double wall corrugated pipes. With its Siemens PLC system, efficient corrugator, large pipe diameter capacity, precision forming machine, and optimized barrel nitriding depth, this extrusion line sets a new standard in double wall corrugated pipe manufacturing technology.

Technical Parameters:

| Forming Machine | 1 Set |

| Screw Channel Structure | Deep Screw |

| Inverter | Siemens |

| Barrel | Hardness Of Barrel HV>940 |

| Outside Diameter | 40mm-1600mm |

| Screw And Barrel | 38crmoaia |

| Barrel Nitriding Depth | 0.4~0.7 Mm |

| Customized | Customized |

| Corrugator | 1 Set Corrugator |

| Main Electrics | Siemens / Schneider |

Applications:

The HUASU Double Wall Corrugated Pipe Extrusion Line (Model: SBG) is a top-of-the-line product for manufacturing plastic corrugated pipes. With its origin in China, this product boasts ISO and CE certifications, ensuring quality and reliability.

Designed for versatility, this corrugated pipe machinery is suitable for a wide range of applications and scenarios. The product finds its place in various industries such as construction, telecommunications, agriculture, and infrastructure development.

Whether you need to produce drainage pipes, cable protection conduits, or sewer pipes, the HUASU Double Wall Corrugated Pipe Extrusion Line is the ideal solution. The deep screw channel structure ensures efficient extrusion, while the 1 set corrugator and forming machine guarantee precise shaping and sizing.

With an outside diameter ranging from 40mm to 1600mm and a maximum pipe diameter of 1600mm, this Corrugated Pipe Production System can meet diverse project requirements. The minimum order quantity of 1 set and a price range of US$50,000 to 5,000,000 make it accessible to both small-scale and large-scale manufacturers.

Packaged securely and delivered within 30-90 days, this product offers flexible payment terms of TT or L/C. With a supply ability of 100 lines, you can rely on the HUASU Double Wall Corrugated Pipe Extrusion Line to enhance your production capabilities.

Customization:

Product Customization Services for the Double Wall Corrugated Pipe Extrusion Line:

- Brand Name: HUASU

- Model Number: SBG

- Place Of Origin: China

- Certification: ISO, CE

- Minimum Order Quantity: 1 SET

- Price: US$50,000-5,000,000

- Packaging Details: Standard Package

- Delivery Time: 30-90 Days

- Payment Terms: TT, L/C

- Supply Ability: 100 Line

- Main Electrics: Siemens / Schneider

- Specification: 32*1500mm

- Screw Channel Structure: Deep Screw

- Inverter: Siemens

- Barrel: Hardness Of Barrel HV>940

Customize your drainage pipe machine with the HDPE Double Wall Corrugated Pipe Machine today!