Single or Double Wall Corrugated Pipe Production Line and 40cr Casting Mold Material for Production:

Product Description:

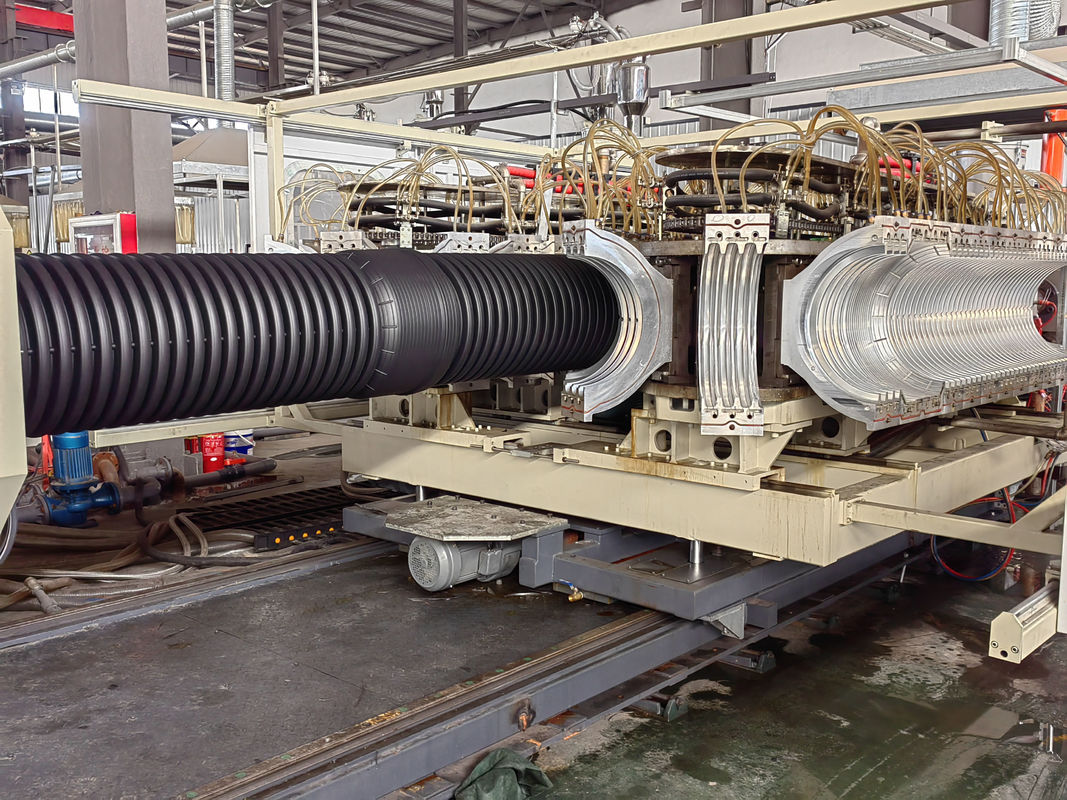

The Double Wall Corrugated Pipe Extrusion Line is a high-quality machine designed for the production of double wall corrugated pipes. With advanced features and components, this extrusion line is ideal for manufacturing corrugated pipes used in various applications such as drainage, sewage, and more.

Equipped with a helical gear, this corrugation pipe machine ensures smooth and efficient operation, allowing for precise control over the production process. The use of helical gear technology enhances the durability and reliability of the equipment, making it a dependable choice for long-term use.

Designed for forming pipes through a vacuum process, the Double Wall Corrugated Pipe Extrusion Line offers superior performance in creating high-quality corrugated pipes. The vacuum forming type ensures that the pipes produced are consistent in shape and dimension, meeting the required standards for various applications.

With a diameter range of 16-1500mm, this Corrugated Pipe Production Equipment provides versatility in producing pipes of different sizes to meet specific project requirements. Whether for small-scale applications or large infrastructure projects, this extrusion line can cater to a wide range of pipe diameter needs.

The mould material used in this Double Wall Corrugated Pipe Processing Equipment is aluminium alloy, known for its durability, heat resistance, and precision in shaping the pipes. The use of aluminium alloy ensures that the moulds can withstand the rigors of continuous production and maintain the desired corrugation pattern with accuracy.

Overall, the Double Wall Corrugated Pipe Extrusion Line is a reliable and efficient solution for manufacturing high-quality corrugated pipes. With its helical gear technology, vacuum forming type, versatile diameter range, and durable aluminium alloy mould material, this extrusion line offers the capabilities needed to produce top-notch double wall corrugated pipes for various applications.

Technical Parameters:

| Gear Type |

Helical Gear |

| Product Type |

Corrugate Pipe Machinery |

| Diameter |

16-1500mm |

| Mould Material |

Aluminium Alloy |

| Mold Material |

40cr Casting |

| Max Pipe Diameter |

1600mm |

| Application |

Drainage, Sewage Etc |

| Forming Type |

Vacuum |

| Materials |

PE/PP/PVC |

Applications:

The HUASU Double Wall Corrugated Pipe Extrusion Line, model SBG, is a high-quality machine designed and manufactured in China. This product is certified with ISO and CE standards, ensuring its reliability and performance. With a minimum order quantity of 1 set and a price range from US$50,000 to US$5,000,000, this extrusion line offers great value for your investment.

The packaging details for this product include a standard package, and the delivery time ranges from 30 to 90 days. Payment terms accepted are TT and L/C, providing flexibility to customers. With a supply ability of 100 lines, HUASU ensures efficient production and delivery of the Double Wall Corrugated Pipe Extrusion Line.

Constructed with mould material made of Aluminium Alloy, this machine is durable and long-lasting. The application occasions and scenarios for this cable dust pipe machine include drainage, sewage systems, and more. The Double Wall Corrugated Pipe Extrusion Line can handle a maximum pipe diameter of 1600mm, with a diameter range from 16mm to 1500mm.

Equipped with helical gears, this corrugated pipe making machine offers precise and efficient operation. Whether you are looking to set up a Corrugated Pipe Production System for industrial or commercial use, the HUASU Double Wall Corrugated Pipe Extrusion Line is a reliable choice.

Customization:

Product Customization Services for the Double Wall Corrugated Pipe Extrusion Line:

Brand Name: HUASU

Model Number: SBG

Place Of Origin: China

Certification: ISO, CE

Minimum Order Quantity: 1 SET

Packaging Details: Standard Package

Delivery Time: 30-90 Days

Payment Terms: TT, L/C

Supply Ability: 100 Line

Forming Type: Vacuum

Mould Material: Aluminium Alloy

Diameter: 16-1500mm

Mold Material: 40cr Casting

Application: Drainage, Sewage Etc

Keywords: Plastic Corrugated Pipe Production Line, Double Wall Corrugated Pipe Mould, Double Wall Corrugated Pipe Extrusion Machine

Please contact with me for more details:

Sandy Liu

Shandong Huasu Plastic Technology Co., Ltd.

WhatsApp: +86 13864817239

Wechat: +86 1386481739

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!