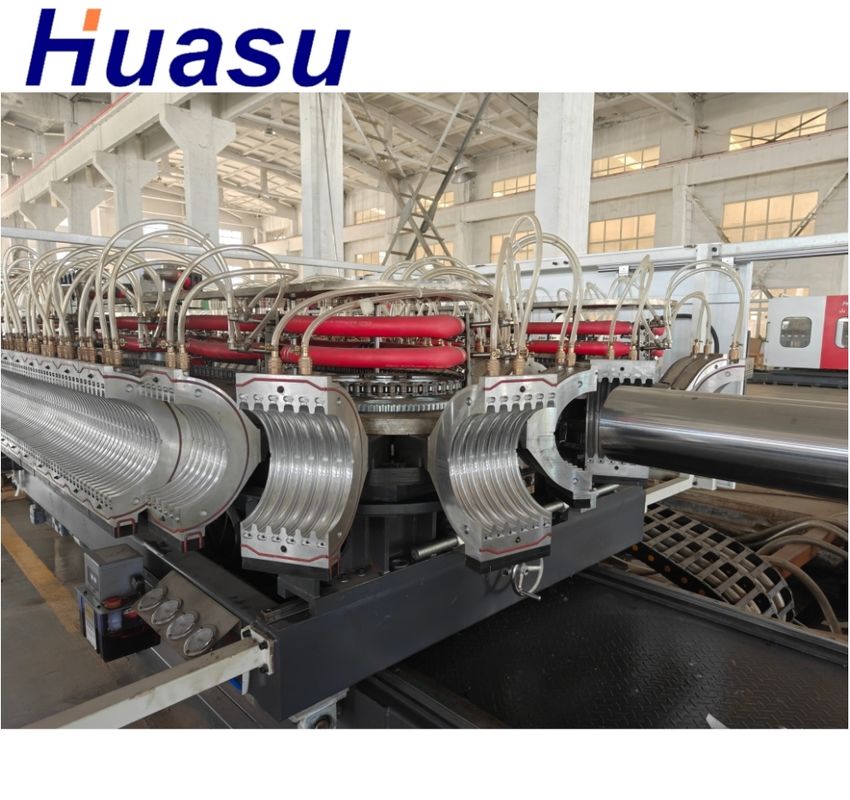

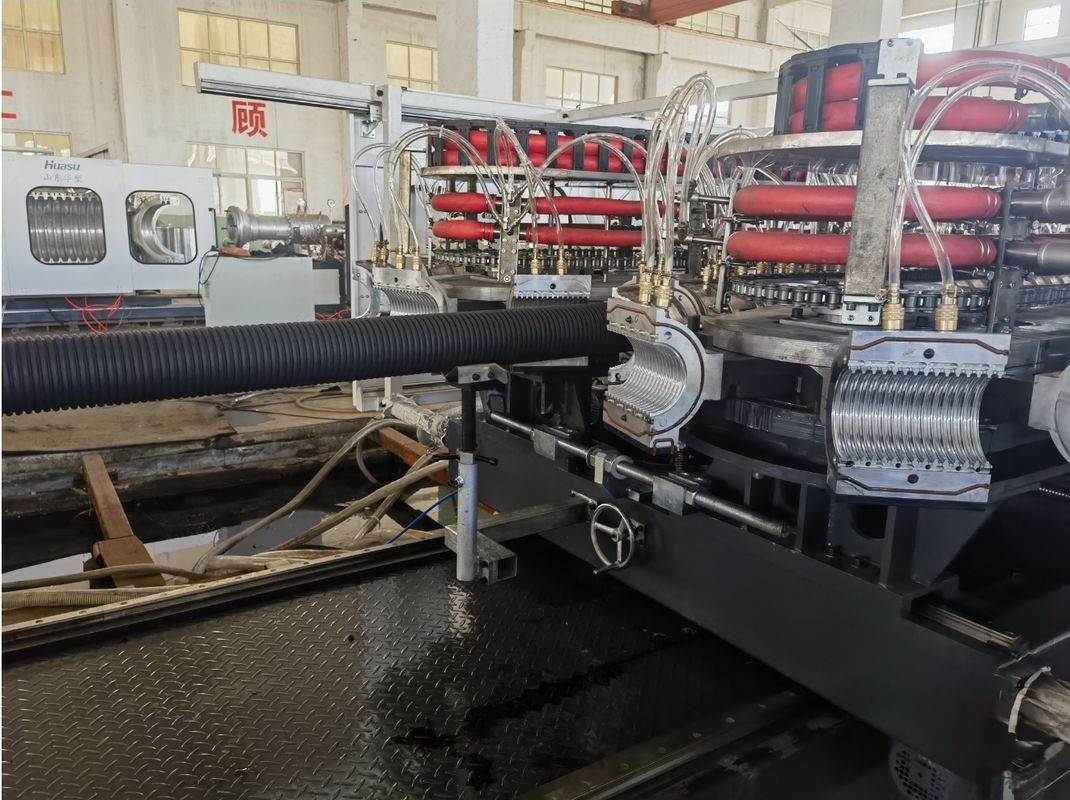

Siemens Contactor Double Wall Corrugated Pipe Extrusion Line for Pipe Diameter Range 32mm-1600mm:

Product Description:

The Double Wall Corrugated Pipe Extrusion Line is a state-of-the-art piece of equipment that is designed to meet the high demands of the industry. With a focus on efficiency and quality, this extrusion line is equipped with top-of-the-line components and features to ensure optimal performance.

Powered by a reliable Siemens motor, this extrusion line delivers consistent and powerful operation to meet production needs. The barrel screw of this machine is made with high-quality materials, boasting a hardness of HV>740 to withstand the rigors of continuous use and deliver precise extrusion results.

Water cooling is the chosen method for maintaining optimal operating temperatures, ensuring the extrusion process runs smoothly and efficiently. This cooling method is effective in dissipating heat generated during operation, contributing to the longevity of the equipment.

Operating at an automatic grade, this extrusion line offers ease of use and efficiency in production processes. The automatic features streamline operations, reducing manual intervention and improving overall productivity.

The mould material of this extrusion line is made of aluminium alloy, known for its durability and heat resistance. The Double Wall Corrugated Pipe Extrusion Line is equipped with a high-quality Double Wall Corrugated Pipe Mould that ensures precise and consistent pipe manufacturing.

When it comes to Corrugated Pipe Manufacturing Machinery, the Double Wall Corrugated Pipe Extrusion Line stands out for its reliable performance and quality construction. The equipment is designed to meet the demands of modern manufacturing processes, offering efficiency and precision in producing double wall corrugated pipes.

With top-of-the-line components and advanced features, the Double Wall Corrugated Pipe Extrusion Line is a valuable addition to any manufacturing facility looking to enhance their production capabilities. Invest in the best Double Wall Corrugated Pipe Equipment available on the market and experience increased efficiency and quality in your manufacturing operations.

Features:

- Product Name: Double Wall Corrugated Pipe Extrusion Line

- Gear Material: 20CrMnTi

- Motor: Siemens

- Product Type: Pipe Extrusion Line

- Screw Material: 38CrMoALA

- Contactor: Siemens, Schneider

Technical Parameters:

| Cooling Way | Water Cooling |

| Barrel Screw | Hardness Of Screw HV>740 |

| Materials | PE/PP/PVC |

| Gear Material | 20CrMnTi |

| Automatic Grade | Automatic |

| Motor | Siemens |

| Specification | 32-1600mm |

| Contactor | Siemens, Schnerder |

| Mould Material | Aluminium Alloy |

| Screw Material | 38CrMoALA |

Applications:

When considering the Product Application Occasions and Scenarios for the HUASU SBG Double Wall Corrugated Pipe Extrusion Line, it is essential to highlight its versatility and efficiency in various industries. This Automatic Double Wall Corrugated Pipe Machine from China is specifically designed for the production of high-quality corrugated pipes with diameters ranging from 32mm to 1600mm.

The Double Wall Corrugated Pipe Manufacturing Machinery is suitable for a wide range of applications, including underground cable protection, drainage systems, sewage pipelines, and industrial wastewater transportation. Its robust construction and precise engineering make it a reliable choice for infrastructure projects, construction sites, and municipal utilities.

With ISO and CE certifications, this Double Wall Corrugated Pipe Extrusion Machine guarantees compliance with international quality standards, ensuring durability and performance. The use of premium materials such as PE, PP, and PVC further enhances the product's reliability and longevity.

Customers can benefit from the HUASU SBG extrusion line's efficient operation, thanks to advanced components from reputable brands like Siemens and Schnerder. The Motor and Contactor provided by Siemens ensure smooth production processes and minimal downtime.

Whether the project requires standard 32mm pipes or larger 1600mm pipelines, this machinery offers a wide range of specifications to meet diverse needs. The Supply Ability of 100 lines ensures timely delivery, with a Minimum Order Quantity of just 1 set.

Please contact with me for more details:

Sandy Liu

Shandong Huasu Plastic Technology Co., Ltd.

WhatsApp: +86 13864817239

Wechat: +86 1386481739

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews