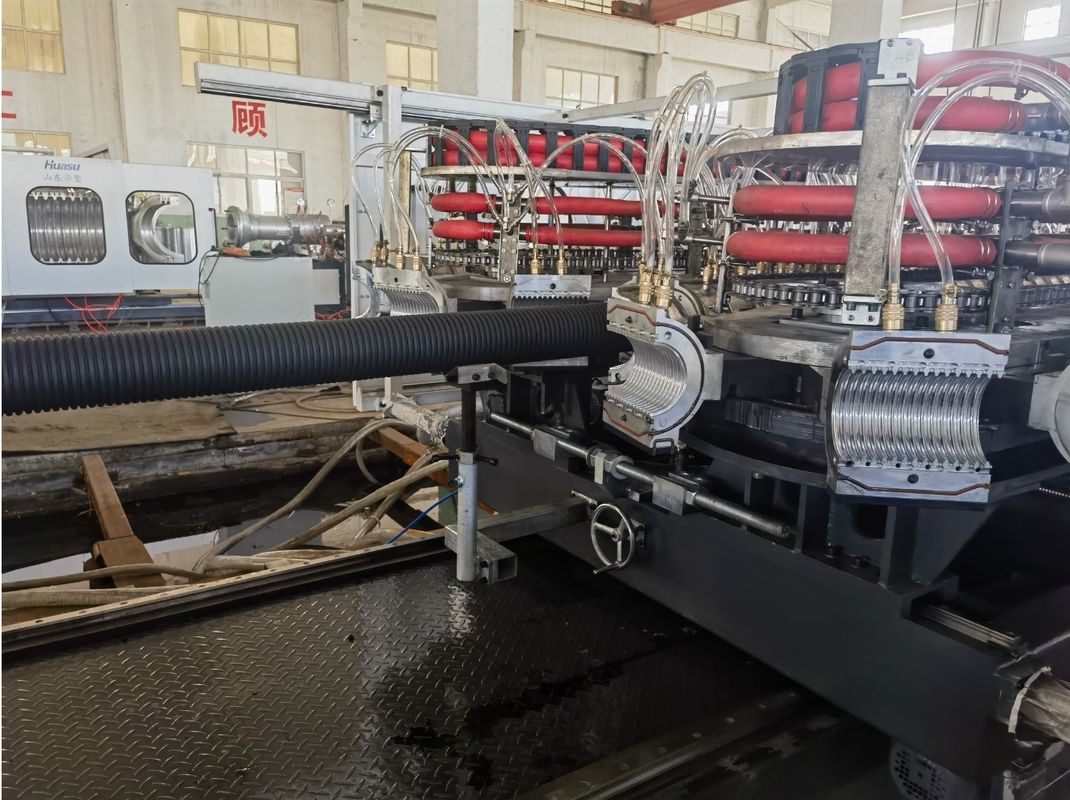

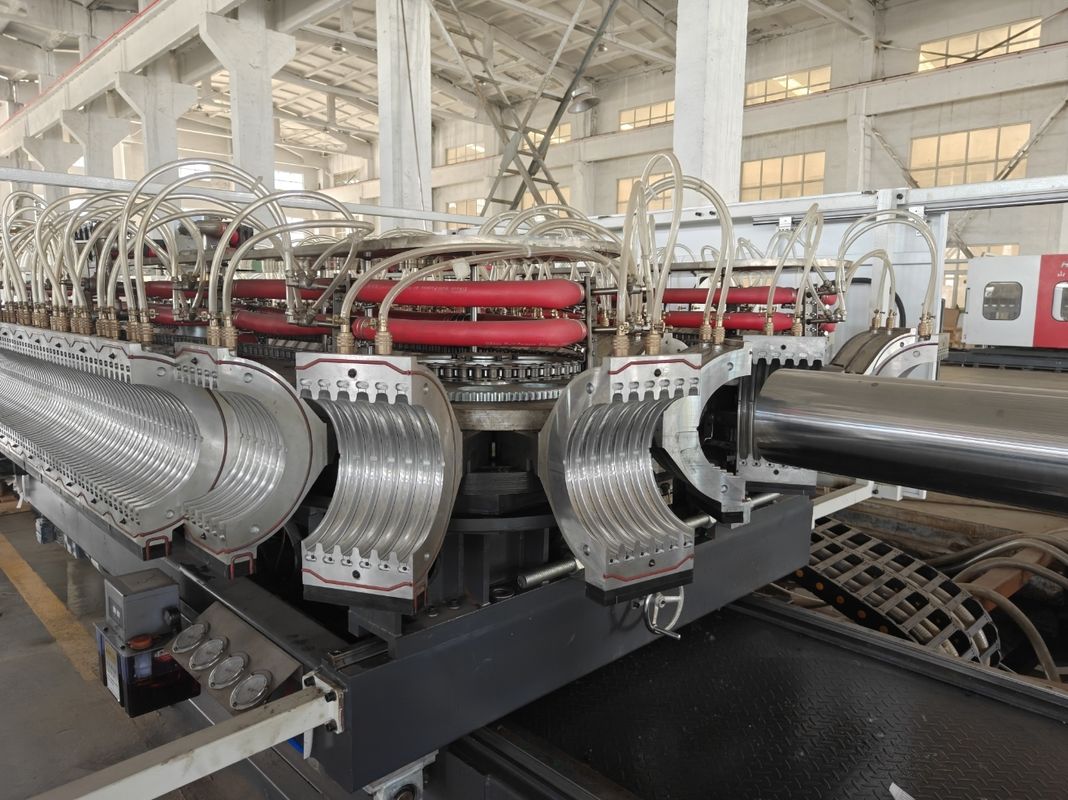

Customizable Double Wall Corrugated Pipe Extrusion Line with Aluminium Alloy Mould Material and Schneider Contactor:

Product Description:

The Double Wall Corrugated Pipe Extrusion Line is a cutting-edge product designed to meet the demands of the modern industry for high-quality and efficient production of double wall corrugated pipes. This pipe extrusion line is a comprehensive solution for manufacturing double wall corrugated pipes, offering state-of-the-art technology and reliable performance.

With a water cooling system, this extrusion line ensures efficient and uniform cooling of the pipes during the production process. The water cooling system helps maintain the desired temperature levels, resulting in superior pipe quality and consistency.

The gear material used in this extrusion line is 20CrMnTi, known for its exceptional strength and durability. This high-quality gear material ensures smooth operation and longevity of the equipment, making it a reliable choice for long-term production needs.

Equipped with Siemens and Schnerder contactors, this extrusion line guarantees reliable and efficient performance. These reputable brands are known for their quality electrical components, ensuring stable operation and safety during the production process.

Operating at an automatic grade, this extrusion line offers a high level of automation for increased efficiency and productivity. The automatic grade eliminates the need for manual intervention, reducing labor costs and minimizing the risk of errors during operation.

As a leading provider of Double Wall Corrugated Pipe Production Solutions, this extrusion line is a versatile and reliable choice for manufacturers looking to enhance their production capabilities. Whether you are producing drainage pipes, sewer pipes, or cable protection pipes, this equipment offers the flexibility and efficiency needed to meet a wide range of production requirements.

With its advanced technology and robust construction, this Double Wall Corrugated Pipe Processing Equipment is designed to deliver superior performance and durability. The corrugated pipe machinery included in this extrusion line is engineered to meet the highest industry standards, ensuring consistent and reliable production of double wall corrugated pipes.

Overall, the Double Wall Corrugated Pipe Extrusion Line is a top-of-the-line solution for manufacturers seeking a high-quality and efficient production process for double wall corrugated pipes. With its water cooling system, durable gear material, reputable contactors, and automatic grade operation, this extrusion line offers a comprehensive and reliable solution for a wide range of production needs.

Features:

- Product Name: Double Wall Corrugated Pipe Extrusion Line

- Product Type: Pipe Extrusion Line

- Specification: 32-1600mm

- Automatic Grade: Automatic

- Screw Material: 38CrMoALA

- Materials: PE/PP/PVC

Technical Parameters:

| Materials |

PE/PP/PVC |

| Specification |

32-1600mm |

| Mould Material |

Aluminium Alloy |

| Automatic Grade |

Automatic |

| Cooling Way |

Water Cooling |

| Product Type |

Pipe Extrusion Line |

| Pipe Diameter Range |

32mm-1600mm |

| Contactor |

Siemens, Schnerder |

| Gear Material |

20CrMnTi |

| Motor |

Siemens |

Applications:

Product Application Occasions and Scenarios for the Double Wall Corrugated Pipe Extrusion Line:

The HUASU SBG Double Wall Corrugated Pipe Extrusion Line is a versatile and high-quality machine designed for the production of double wall corrugated pipes. With its exceptional attributes such as a hardness of screw HV>740, aluminium alloy mould material, and water cooling system, this equipment is ideal for various applications in different industries.

1. Industrial Applications: The Double Wall Corrugated Pipe Forming Machine can be used in industrial settings for the manufacturing of drainage pipes, cable protection tubes, and sewage pipes. Its precision and efficiency make it suitable for heavy-duty operations in factories and production facilities.

2. Infrastructure Projects: This Double Wall Corrugated Pipe Processing Equipment is perfect for infrastructure projects such as road construction, underground utilities, and stormwater management systems. The pipes produced by this equipment are durable, reliable, and meet industry standards.

3. Construction Industry: Contractors and builders can benefit from the Double Wall Corrugated Pipe Equipment for applications like foundation drainage, culvert systems, and land drainage. The high supply ability of 100 lines ensures timely completion of projects.

4. Municipal Engineering: Municipalities can utilize the SBG Double Wall Corrugated Pipe Extrusion Line for sewer line installations, water management systems, and public works projects. The ISO and CE certifications guarantee the quality and safety of the produced pipes.

5. Agricultural Sector: Farmers and agricultural businesses can make use of the Double Wall Corrugated Pipe Extrusion Line for irrigation systems, drainage solutions, and agricultural water management. The wide range of specifications from 32mm to 1600mm caters to various farming needs.

Overall, the HUASU Double Wall Corrugated Pipe Extrusion Line is a reliable and efficient solution for a wide range of applications across different industries. With its premium features and competitive price range of US$50,000-5,000,000, this equipment offers excellent value for money. The standard packaging, quick delivery time of 30-90 days, and flexible payment terms of TT and L/C make it a convenient choice for businesses looking to invest in top-notch pipe extrusion technology.

Please contact with me for more details:

Sandy Liu

Shandong Huasu Plastic Technology Co., Ltd.

WhatsApp: +86 13864817239

Wechat: +86 1386481739

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews