PLC Control System And Touch Screen DWC Pipe Extrusion Line for and Customizable Production

Product Description:

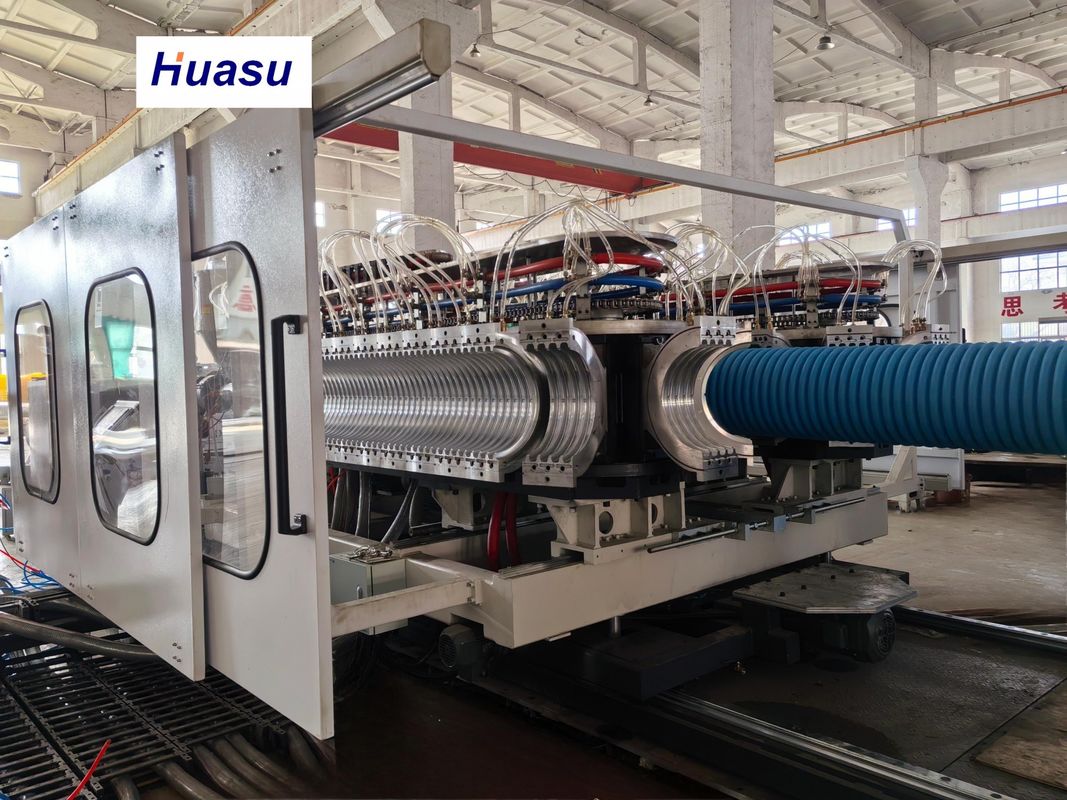

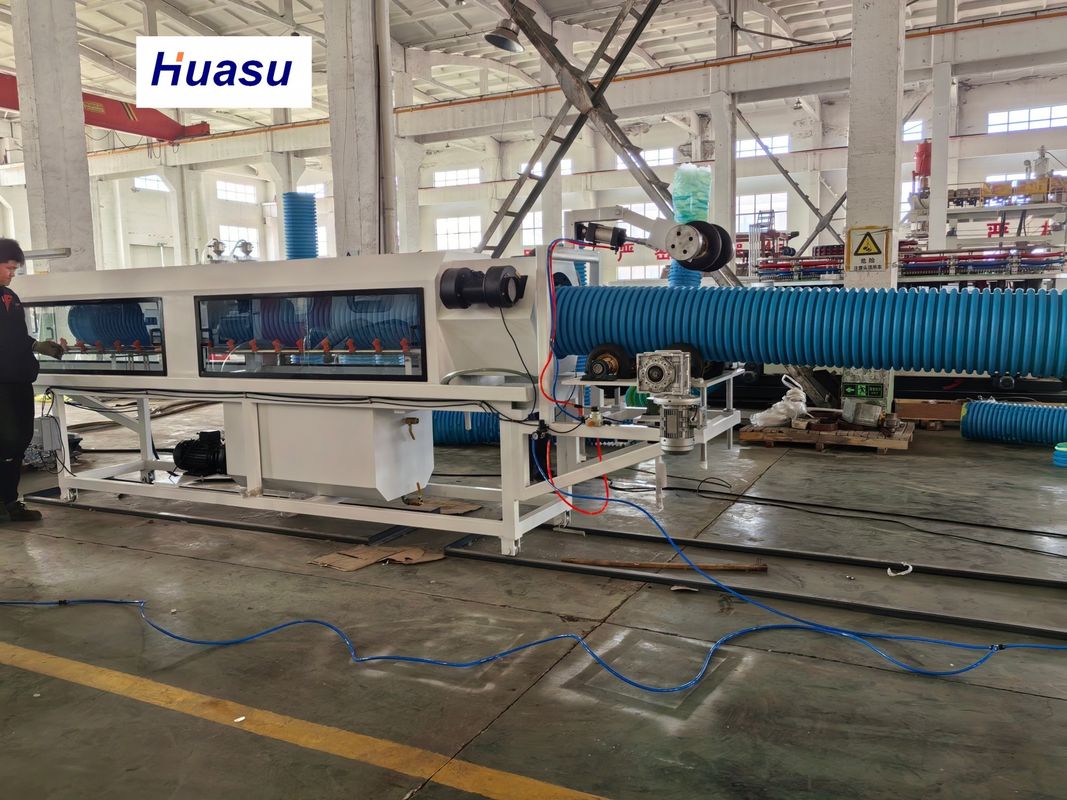

The double wall corrugated pipe line is the 3rd generation of the improved product of Shandong HUASU. The output of the extruder and the production speed of the pipe are greatly increased by 20-40% compared with the previous product.

Online belling can be achieved to ensure the performance of the formed corrugated pipe products. The production line adopts Siemens PLC system for efficient control and management.

Features:

Pressure water-cooling for mould blocks: This feature significantly boosts production speed by efficiently cooling mould blocks.

Low energy consumption: The system is designed to reduce energy usage, aiding in lowering overall production costs.

Efficient vacuum system: A specialized vacuum system ensures precise pipe formation for perfect results.

Mould block temperature control system: This system optimizes pipe quality, enhancing both the appearance and internal structure of the pipes.

Easy and quick changeover: Switching between different mould sizes is seamless, with toolings that are compatible with various production lines.

Full-automation: The entire extrusion line operates automatically, streamlining the production process.

Corrugator and extruders synchronization: These components are controlled in sync to ensure efficient pipe production.

Harden-treated screw and barrels: The system incorporates durable screw and barrels for extended lifespan and durability.

Remote Service: Get assistance easily with the availability of remote service options for added support.

Technical Parameters:

| Capacity |

60-2000kg/h |

| Electric Element |

Siemens Brand |

| Control System |

PLC Control System And Touch Screen |

| Features |

High Productivity, Competitive Price, Energy Saving, Automatic |

| Processing Procedure |

Raw Material Feeding In Screw Extruder, Shaping In Forming Machine, Water Cooling Tank Cooling, Online Cut By Cutting Machine |

| Plastic Raw Material Processed |

PVC/PE/MPP/PA/HDPE |

| Finished Product |

Drainage Pipe, Municipal Engineering, Underground Sewage Pipe, Electric Cable Conduit |

| Product Type |

Double Wall Corrugated Pipe Extrusion Line |

| Pipe Diameter |

32-1600mm |

| Application |

Drainage/Sewage/Cable Duct/Electric Conduit/Fresh Air Ventilation Pipe |

Applications:

Our Plastic Pipe Making Machine is specially designed to manufacture plastic pipes utilized in water supply, water drainage, and electric cable conduits.

The machine is engineered with precision to create premium plastic pipes that adhere to the standards for different uses, including water transportation, drainage system facilitation, and electric cable protection.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews