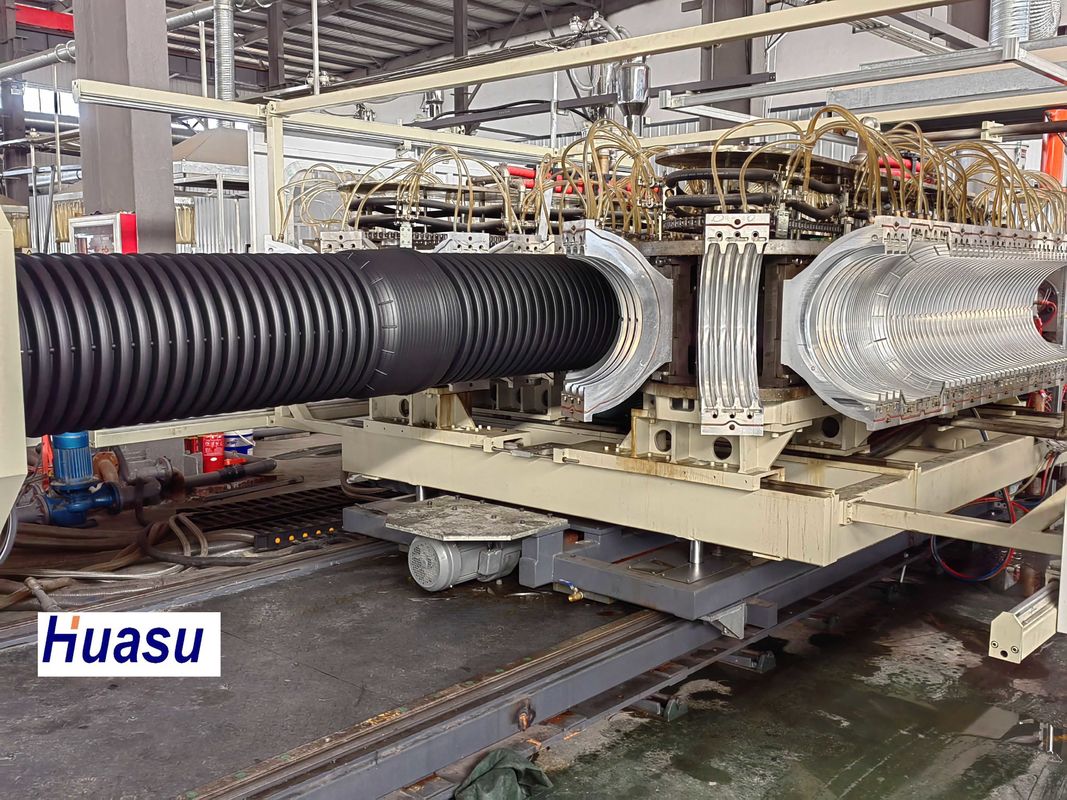

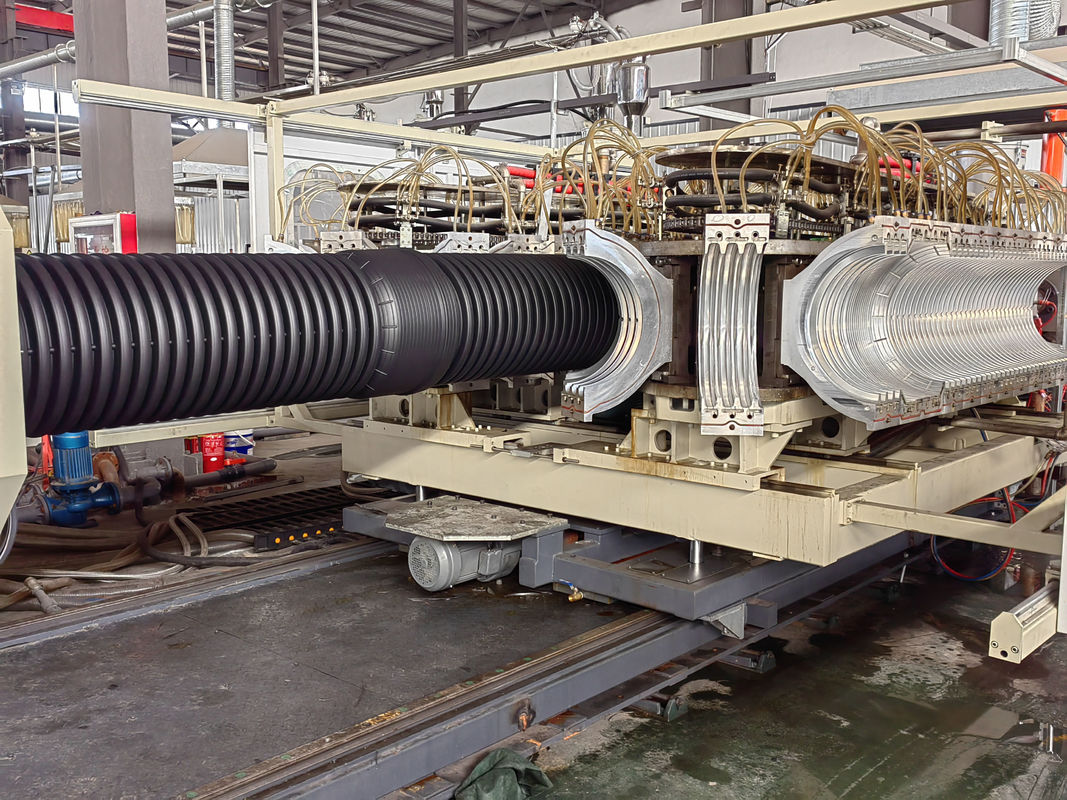

High Speed Double Wall Corrugated Pipe Extrusion Line Featuring Siemens / Schneider Main Electrics:

Product Description:

The Automated Double Wall Corrugated Pipe Production Line is a cutting-edge solution for efficient and high-quality production of double wall corrugated pipes. This state-of-the-art Corrugated Pipe Forming Machine is equipped with a single-screw extruder, ensuring precise control over the extrusion process. Operating at high speed, this equipment is designed to meet the demands of modern manufacturing environments.

One of the key features of this Double Wall Corrugated Pipe Equipment is its water cooling method, which helps maintain optimal operating temperatures and enhances the overall efficiency of the production line. The cooling system ensures consistent product quality and minimizes downtime, making it an ideal choice for high-volume production.

With a customizable design, this extrusion line can be tailored to meet specific production requirements. Whether producing small batches or large quantities, the Capacity of 100-2000Kg/h provides flexibility and scalability to adapt to changing production needs. This level of customization ensures that the equipment can efficiently meet the demands of various applications and production volumes.

Features:

- Product Name: Double Wall Corrugated Pipe Extrusion Line

- Barrel Nitriding Depth: 0.4~0.7 Mm

- Screw No: Single-screw

- Cooling Method: Water Cooling

- Main Electrics: Siemens / Schneider

- Product Type: Corrugated Pipe Extrusion Line

Technical Parameters:

| Customized |

Customized |

| Plc |

Siemens |

| Product Type |

Corrugated Pipe Extrusion Line |

| Main Electrics |

Siemens / Schneider |

| Cooling Method |

Water Cooling |

| Water Sleeve Material |

High Quality Steel |

| Screw Material |

38CrMoALA |

| Application |

Drainage/Sewage/Water Supply |

| Screw No |

Single-screw |

| Barrel Nitriding Depth |

0.4~0.7 Mm |

Applications:

The HUASU SBG Double Wall Corrugated Pipe Extrusion Line is a cutting-edge solution for automated double wall corrugated pipe production. With its high-speed capabilities and advanced features, this machine is ideal for a wide range of application occasions and scenarios.

Manufacturers looking for efficient and reliable double wall corrugated pipe production solutions will find the HUASU SBG Extrusion Line to be a perfect fit. Whether producing pipes for drainage systems, telecommunications, or automotive applications, this machine offers the versatility and performance needed to meet various industry requirements.

Originating from China, this state-of-the-art extrusion line is ISO and CE certified, ensuring high quality and compliance with international standards. With a minimum order quantity of just 1 set and a price range of US$50,000-5,000,000, the HUASU SBG Extrusion Line provides cost-effective manufacturing solutions for businesses of all sizes.

Equipped with Siemens PLC technology and constructed with durable 38CrMoALA screw material, this machine offers a reliable and efficient production process. The barrel nitriding depth of 0.4-0.7mm further enhances the durability and performance of the extrusion line, making it suitable for long-term and high-capacity operation.

With a supply ability of 100 lines, a delivery time of 30-90 days, and payment terms including TT and L/C, the HUASU SBG Double Wall Corrugated Pipe Extrusion Line is designed to meet the needs of modern manufacturing operations. Whether producing at a capacity of 100-2000kg/h, this machine delivers consistent and high-quality results for a wide range of production requirements.

For manufacturers seeking a high-speed, automated double wall corrugated pipe manufacturing machine, the HUASU SBG Extrusion Line offers a reliable and efficient solution. With its advanced features, robust construction, and proven performance, this machine is a top choice for businesses looking to optimize their production processes.

Packaged in standard packaging for secure transportation and easy setup, the HUASU SBG Extrusion Line is a complete solution for manufacturers in need of a reliable and high-performance double wall corrugated pipe production machine.

Please contact with me for more details:

Sandy Liu

Shandong Huasu Plastic Technology Co., Ltd.

WhatsApp: +86 13864817239

Wechat: +86 1386481739

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!