All Products

Contact Person :

Sisi Zhao

Phone Number :

+86-13853290988

PLC Corrugated Pipe Extrusion Line for 32-1600mm Double Wall Pipes

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Machine | Corrugated Pipe Line | Transport Package | Film Package Or Woodcase Package |

|---|---|---|---|

| Product Type | Plastic Corrugated Pipe With Double Wall | Temperature Controller | Temperature Sensor |

| Pipe Diameter Range | 32-1600mm | Plastic Machine | Corrugated Pipe Equipment |

| Extruder Type | Single Screw Extruder | Monitoring System | PLC |

| Highlight | Corrugated Pipe Extrusion Line,PLC Monitoring Extrusion Line,Smooth corrugated pipe extrusion machine |

||

Product Description

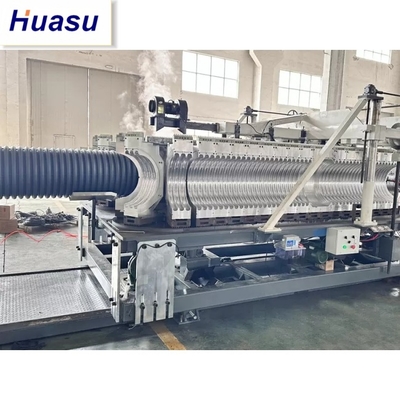

PLC Monitoring System Corrugated Pipe Extrusion Line for Smooth Operation

PLC Monitoring System for Smooth Operation in Corrugated Pipe Extrusion Line

The double wall corrugated pipe line represents the third generation of the enhanced product developed by Shandong HUASU. In contrast to its predecessor, the extruder's output and the production speed of the pipe have experienced a significant increase of 20-40%. This technological improvement enables continuous online belling, which in turn enhances the performance of the corrugated pipe products created.

Additionally, the system incorporates Siemens PLC technology, well-known for its reliability and efficiency in industrial automation. This ensures a smooth operation and precise control of the entire production process, leading to improved overall performance and productivity.

Key Features

- Pressure water-cooling integrated into mould blocks significantly boosts production speed

- Low-energy consumption technology reduces production costs while maintaining affordability

- Efficient vacuum system ensures creation of flawless pipes with superior quality

- Mould block temperature control system optimizes both external appearance and internal integrity

- Easy and rapid changeover between different mould sizes with compatible toolings

- Fully automatic operation with synchronized corrugators and extruders

- Hardened treated screws and barrels for prolonged lifespan and durability

- Remote service accessibility for convenient maintenance and troubleshooting

Technical Parameters

| Pipe materials | PVC / PE / MPP / PA / HDPE |

|---|---|

| Monitoring System | PLC |

| Machine Name | Double Wall Corrugated Pipe Extrusion Line |

| Plastic Machine | Corrugated Pipe Equipment |

| Temperature Controller | Temperature Sensor |

| Unique Advantage | High Productivity, Competitive Price, Energy Saving, Automatic |

| Product | Drainage Pipe, Municipal Engineering, Underground Sewage Pipe, Electric Cable Conduit Pipe Production Line |

| Product Type | Plastic Corrugated Pipe With Double Wall |

| Transport Package | Film Package Or Woodcase Package |

| Pipe Diameter Range | 32-1600mm |

Applications

- Manufacturing plastic pipes for water supply, drainage, and electric cable conduits

- Production of pipes used in municipal engineering and underground sewage systems

- Creation of conduit pipes for electrical cable housing and protection

Recommended Products