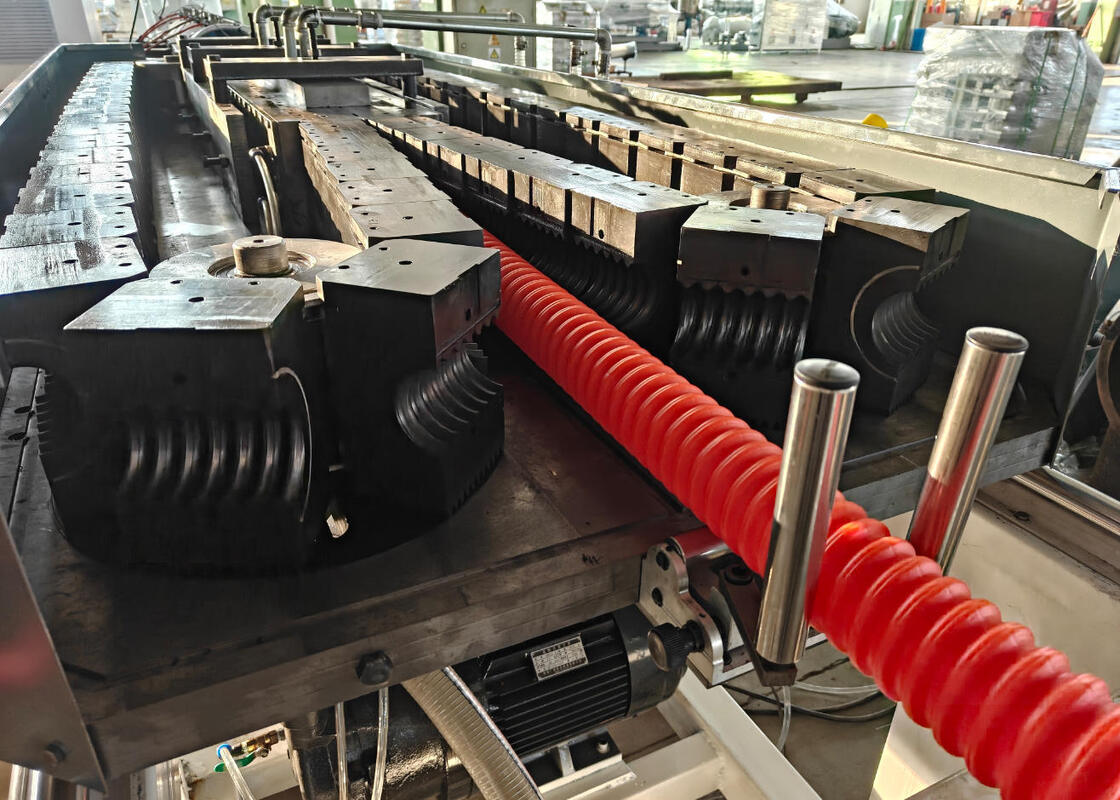

High Output Double Wall Corrugated Pipe Extrusion Line

This advanced Double Wall Corrugated Pipe Extrusion Line is engineered for high-efficiency production of superior quality double wall corrugated pipes. Designed specifically for processing PP (Polypropylene), PE (Polyethylene), and PVC (Polyvinyl Chloride) raw materials, this system represents premier High-Density Polyethylene Corrugated Pipe Equipment, delivering exceptional performance for durable and flexible corrugated pipe manufacturing.

Advanced Cooling Technology

The extrusion line features an innovative continuous pressure water cooling system that ensures uniform cooling throughout the production process. This advanced cooling method accelerates production speeds while enhancing dimensional stability and product quality by reducing internal stresses and preventing deformation.

Premium Siemens Electrical Components

Equipped with main electrical components from Siemens, this system guarantees precise control accuracy, operational safety, and energy efficiency. The integration of these high-quality parts ensures smooth operation with minimal downtime, maintaining consistent output and stringent quality standards.

Robust Integral Extruder Design

Featuring an integral type extruder assembly, this corrugated pipe machine provides enhanced mechanical stability and simplified maintenance. The unified structure optimizes material flow and shear conditions, producing pipes with uniform wall thickness and superior mechanical properties for long service life.

Customizable Production Solutions

The extrusion line offers full customization to meet specific production requirements including pipe diameter, wall thickness, and output capacity. This flexibility ensures compatibility with various raw materials and production targets for diverse industrial applications.

Key Features

- Product Name: Double Wall Corrugated Pipe Extrusion Line

- Raw Material Compatibility: PP, PE, and PVC

- Assembly Structure: Integral Type Extruder for efficient production

- Production Capacity: 100kg/h to 2000kg/h

- Electrical Components: Premium Siemens electric parts

- Full Customization: Tailored to specific production requirements

- Ideal for corrugated pipe machinery and electric conduit pipe making applications

- High-performance design ensuring durability and precision

Technical Specifications

| Output |

High Output Double Wall Corrugated Pipe Equipment |

| Cooling System |

Water Cooling |

| Assembly Structure |

Integral Type Extruder |

| Customization |

Customized |

| Raw Material |

PP/PE/PVC |

| Screw Configuration |

Single-screw |

| Water Cooling Method |

Pressure Water Cooling Continuously |

| Electrical System |

Siemens |

| Production Capacity |

100kg/h - 2000kg/h |

| Main Electrical Parts |

Siemens Brand |

Applications & Industries

The HUASU Double Wall Corrugated Pipe Extrusion Line (Model SBG) is certified by ISO and CE standards and serves multiple industries including construction, agriculture, telecommunications, and drainage systems. This Plastic Pipe Manufacturing Equipment produces durable, lightweight, and flexible corrugated pipes essential for:

• Underground cable protection systems

• Water drainage and sewage systems

• Conduit and pipeline applications

• Various environmental and infrastructural scenarios

With production capacities from 100kg/h to 2000kg/h, standard packaging, and delivery within 30-90 days, this equipment supports both small-scale manufacturers and large industrial operations with flexible payment terms including TT and L/C.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews