All Products

Contact Person :

Sisi Zhao

Phone Number :

+86-13853290988

38CrMoAlA Barrel Material Single Wall Corrugated Pipe Extrusion Line with PLC Remote Control and Siemens Schneider Main Electrics

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Usage | Plastic Pipe Extrusion | Barrel Material | 38CrMoAlA |

|---|---|---|---|

| Marketing Type | Ordinary Product | Water Sleeve Material | High Quality Steel |

| Control | PLC With Remote Control | Suitable Materials | PE, PP, PVC, HDPE |

| Machine Name | Corrugated Pipe Extrusion Line | Main Electrics | Siemens / Schneider |

| Highlight | 38CrMoAlA Barrel Material Corrugated Pipe Extrusion Line,PLC With Remote Control Single Wall Corrugated Pipe Extrusion Line,Siemens Schneider Main Electrics Corrugated Pipe Production Line |

||

Product Description

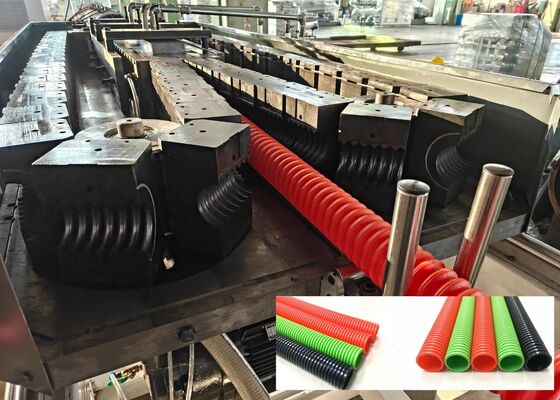

38CrMoAlA Single Wall Corrugated Pipe Production Line

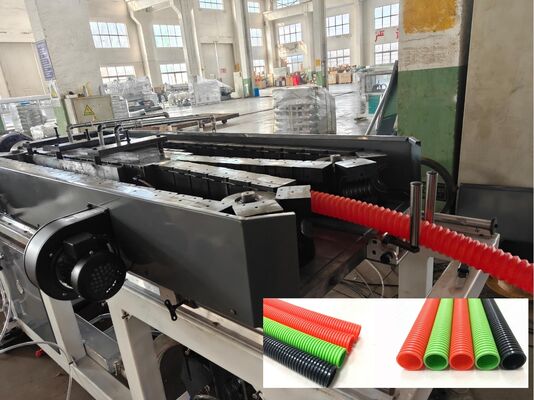

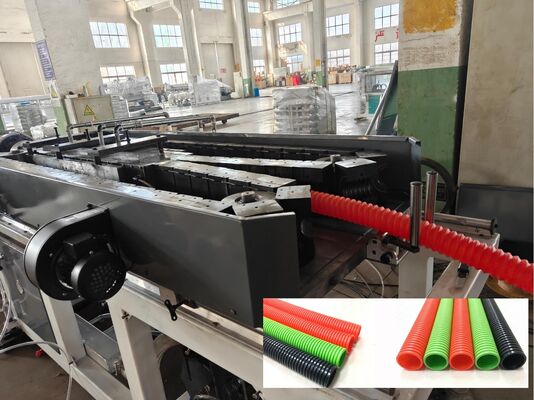

The Single Wall Corrugated Pipe Extrusion Line is a high-performance solution engineered for manufacturing durable corrugated pipes from PE, PP, PVC, and HDPE materials. This versatile production system delivers consistent quality and efficiency for plastic pipe extrusion applications.

Advanced Extrusion Technology

Our corrugated pipe production line utilizes advanced extrusion technology to create lightweight, flexible pipes with excellent mechanical properties. These pipes are ideal for drainage systems, electrical conduit protection, and cable protection applications where resistance to environmental stress is critical.

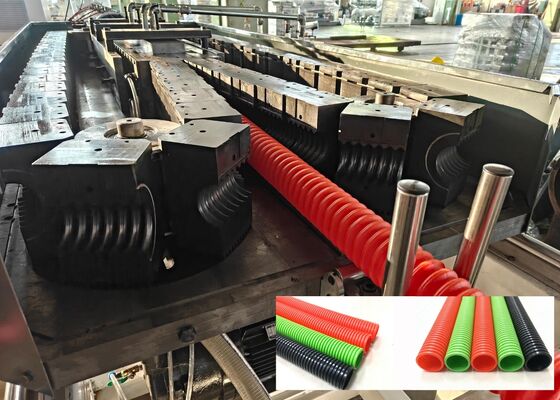

Premium Construction Materials

The extrusion line features a barrel constructed from 38CrMoAlA high-grade alloy steel, providing superior wear resistance and long-term durability. The water sleeve is crafted from high-quality steel to enhance cooling efficiency during the extrusion process, ensuring stable performance under continuous operation.

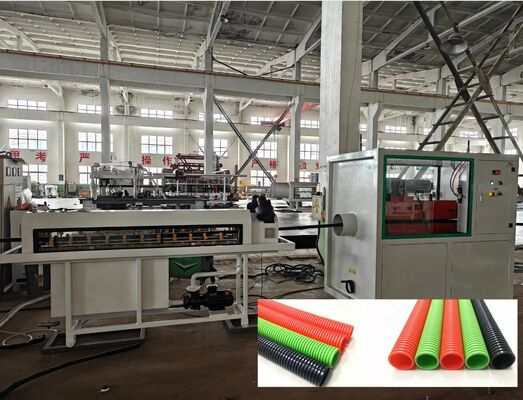

Reliable Control Systems

Equipped with PLC control system featuring remote control functionality and main electrical components from Siemens and Schneider, this production line offers precise parameter control for temperature, screw speed, and motor torque. This ensures consistent pipe quality while reducing material waste.

Key Features

- Fully automatic operation for efficient production

- Specialized single wall corrugated pipe manufacturing

- Water sleeve constructed from high-quality steel

- PLC control system with remote control capability

- Siemens and Schneider main electrical components

- 38CrMoAlA barrel material for enhanced performance

- Advanced corrugated pipe machine ensuring consistent quality

- Compatible with PE, PP, PVC, and HDPE materials

Technical Specifications

| Parameter | Specification |

|---|---|

| Machine Name | Corrugated Pipe Extrusion Line |

| Barrel Material | 38CrMoAlA |

| Water Sleeve Material | High Quality Steel |

| Suitable Materials | PE, PP, PVC, HDPE |

| Main Electrics | Siemens / Schneider |

| Control System | PLC With Remote Control |

| Primary Usage | Plastic Pipe Extrusion |

Applications & Capabilities

The HUASU Single Wall Corrugated Pipe Extrusion Line (Model SBG) is CE and ISO certified, making it suitable for various industrial applications including water supply systems, drainage, agricultural irrigation, and protective conduit systems. With flexible production capabilities, this line can be adapted for manufacturing both single-wall and double-wall corrugated pipes.

Production Capacity: Annual supply ability of 100 sets

Delivery Timeline: 60-90 days after order confirmation

Payment Terms: T/T and L/C accepted

Minimum Order: 1 set

Price Range: USD 10,000 - 1,000,000

Delivery Timeline: 60-90 days after order confirmation

Payment Terms: T/T and L/C accepted

Minimum Order: 1 set

Price Range: USD 10,000 - 1,000,000

Recommended Products