All Products

Contact Person :

Sisi Zhao

Phone Number :

+86-13853290988

Single Wall Corrugated Pipe Extrusion Line with 38CrMoAlA Barrel Material and Siemens Schneider Main Electrics Featuring PLC Remote Control

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Control | PLC With Remote Control | Marketing Type | Ordinary Product |

|---|---|---|---|

| Barrel Material | 38CrMoAlA | Main Electrics | Siemens / Schneider |

| Water Sleeve Material | High Quality Steel | Machine Name | Corrugated Pipe Extrusion Line |

| Usage | Plastic Pipe Extrusion | Suitable Materials | PE, PP, PVC, HDPE |

| Highlight | 38CrMoAlA Barrel Material Corrugated Pipe Extrusion Line,Siemens Schneider Main Electrics Single Wall Corrugated Pipe Extrusion Line,PLC Remote Control Plastic Pipe Extrusion Line |

||

Product Description

Siemens Schneider Main Electrics Corrugated Pipe Extrusion Line

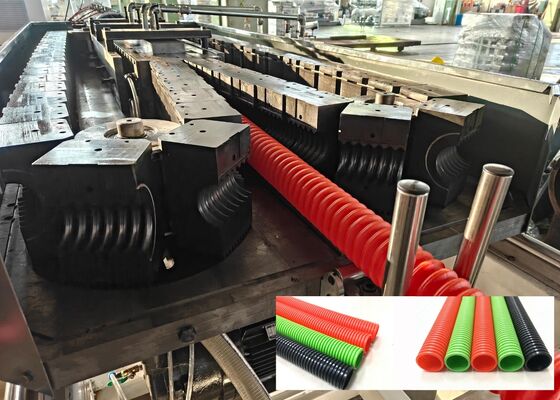

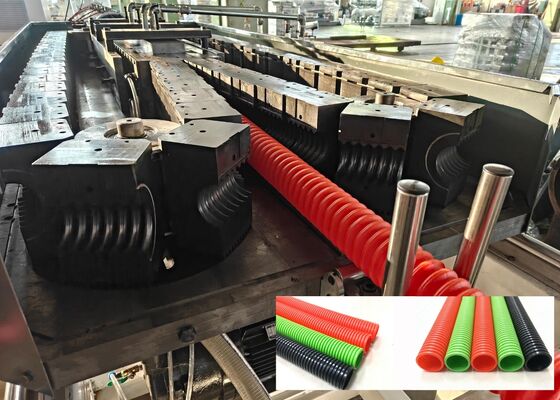

This advanced corrugated pipe extrusion line is engineered for high-performance plastic pipe manufacturing, featuring 38CrMoAlA barrel material for exceptional durability and precision in pipe production.

Advanced Extrusion Technology

The Corrugated Pipe Extrusion Line represents state-of-the-art equipment designed specifically for plastic pipe extrusion applications. Engineered to meet the demanding requirements of cable protection conduit and corrugated cable conduit production, this machine delivers superior performance and reliability through innovative design and robust construction.

Premium Material Construction

Featuring high-quality steel water sleeves for excellent durability and heat resistance, the extrusion line ensures optimal thermal conductivity and corrosion resistance. The barrel is constructed from 38CrMoAlA high-grade alloy, providing exceptional strength, wear resistance, and toughness for handling high-pressure extrusion processes under extreme operating conditions.

Intelligent Control System

Advanced PLC control with remote capabilities enables operators to monitor and adjust production parameters efficiently. This modern control system enhances operational convenience and safety while supporting automation and seamless integration with other production line components.

Key Features

- Product Name: Single Wall Corrugated Pipe Extrusion Line

- Compatible Materials: PE, PP, PVC, HDPE

- Premium Main Electrics: Siemens / Schneider

- High-Strength Barrel Material: 38CrMoAlA

- High-efficiency extrusion process for single wall corrugated pipes

- Compatible with double wall corrugated pipe extrusion technologies

- Durable construction with premium materials for long service life

- Reliable performance with minimal maintenance requirements

Technical Specifications

| Machine Name | Corrugated Pipe Extrusion Line |

| Suitable Materials | PE, PP, PVC, HDPE |

| Control System | PLC With Remote Control |

| Main Electrics | Siemens / Schneider |

| Primary Usage | Plastic Pipe Extrusion |

| Barrel Material | 38CrMoAlA |

| Water Sleeve Material | High Quality Steel |

| Marketing Type | Ordinary Product |

Industrial Applications

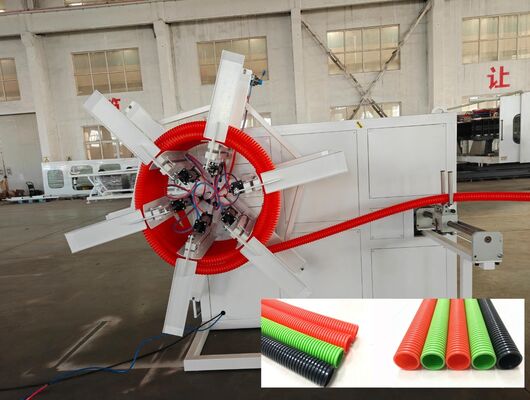

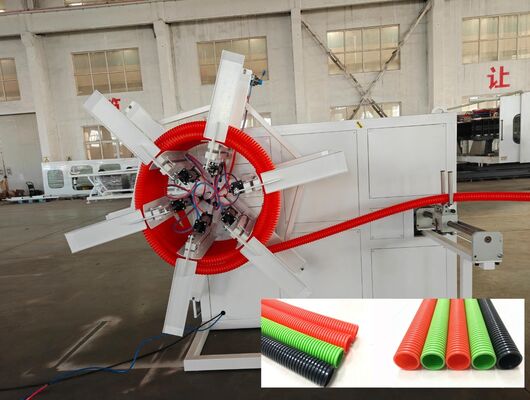

The HUASU Single Wall Corrugated Pipe Extrusion Line (Model SBG) is certified with CE and ISO standards and designed for diverse industrial applications. This high-speed production system is ideal for manufacturing sewer pipes, drainage pipes, and conduit pipes used in municipal, agricultural, and industrial settings.

Applications include urban infrastructure development, stormwater management systems, irrigation projects, and cable protection conduit production. The machine's robust construction and precise corrugation patterns ensure excellent mechanical properties for effective water drainage and soil stabilization projects.

With production capacity of 100 sets annually and flexible payment terms including T/T and L/C, this extrusion line offers scalable solutions for manufacturers worldwide. Delivery is typically completed within 60-90 days with container-standard packaging for safe transportation.

Recommended Products