Single And Double Wall Corrugation Pipe Making Machine Extrusion Line with Automatic Grade Automatic

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Type | Pipe Extrusion Line | Cooling Way | Water Cooling |

|---|---|---|---|

| Specification | 32-1600mm | Pipe Diameter Range | 32mm-1600mm |

| Materials | PE/PP/PVC | Barrel Screw | Hardness Of Screw HV>740 |

| Screw Material | 38CrMoALA | Motor | Siemens |

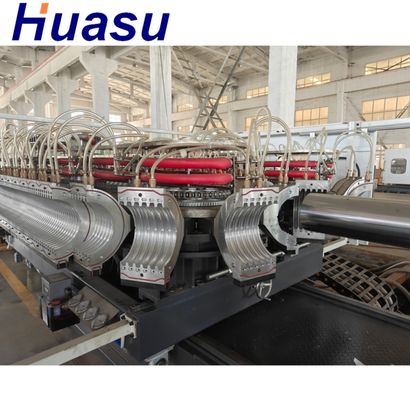

Single And Double Wall Corrugation Pipe Making Machine Extrusion Line with Automatic Grade Automatic:

Product Description:

The Double Wall Corrugated Pipe Extrusion Line is a high-quality and efficient machine designed for the production of corrugated pipes. It is specially engineered to meet the demands of various industries, including cable and dust pipe manufacturing.

Key Features:

- Screw Material: The machine is equipped with a durable screw made of 38CrMoALA material, known for its high strength and resistance to wear and corrosion.

- Specification: With a specification range of 32-1600mm, this extrusion line is versatile and capable of producing a wide range of pipe sizes to suit different applications.

- Mould Material: The mould used in this machine is made of high-quality Aluminium Alloy, ensuring precise and consistent pipe shaping.

- Contactor: The Double Wall Corrugated Pipe Extrusion Line features reputable electrical components from Siemens and Schnerder, known for their reliability and performance.

- Barrel Screw: The hardness of the screw is HV>740, ensuring excellent durability and longevity of the machine, even under high-stress conditions.

Whether you are in the market for a corrugated pipe machine, cable dust pipe machine, or corrugation pipe machine, this extrusion line offers outstanding performance and reliability. Its advanced design and premium materials make it a top choice for businesses looking to enhance their production capabilities and deliver high-quality corrugated pipes.

With the ability to produce pipes ranging from 32mm to 1600mm in diameter, this extrusion line is suitable for a wide range of applications, from residential drainage systems to industrial cable protection. The use of Aluminium Alloy mould ensures that the pipes are accurately formed with uniform corrugations, meeting industry standards and customer requirements.

The inclusion of Siemens and Schnerder contactors further enhances the machine's performance and safety features, providing peace of mind to operators and ensuring smooth operation during the production process. The 38CrMoALA screw material offers exceptional strength and wear resistance, reducing downtime and maintenance costs over the machine's lifespan.

Overall, the Double Wall Corrugated Pipe Extrusion Line is a reliable and efficient solution for businesses seeking a high-performance machine for the production of corrugated pipes. Its quality construction, advanced features, and precision engineering make it a valuable asset for industries looking to streamline their manufacturing processes and deliver superior products to their customers.

Features:

- Product Name: Double Wall Corrugated Pipe Extrusion Line

- Motor: Siemens

- Mould Material: Aluminium Alloy

- Materials: PE/PP/PVC

- Contactor: Siemens, Schnerder

- Specification: 32-1600mm

Technical Parameters:

| Product Type | Pipe Extrusion Line |

| Contactor | Siemens, Schnerder |

| Materials | PE/PP/PVC |

| Barrel Screw | Hardness Of Screw HV>740 |

| Gear Material | 20CrMnTi |

| Cooling Way | Water Cooling |

| Automatic Grade | Automatic |

| Specification | 32-1600mm |

| Motor | Siemens |

| Screw Material | 38CrMoALA |

Applications:

Product Application Occasions and Scenarios for the HUASU Double Wall Corrugated Pipe Extrusion Line (Model: SBG) are diverse and cater to various industries and projects. This advanced Corrugated Pipe Extrusion Production Line, originating from China, is designed to meet the highest standards and is certified with ISO and CE.

The HUASU Double Wall Corrugated Pipe Extrusion Line is suitable for manufacturing High-Density Polyethylene Corrugated Pipe, providing a reliable solution for drainage systems, underground cable protection, sewage pipelines, and more. Its versatility in working with materials such as PE, PP, and PVC makes it an essential equipment for infrastructure projects.

With a minimum order quantity of 1 set and a price range from US$50,000 to US$5,000,000, this equipment offers flexible options for both small-scale and large-scale production needs. The packaging details ensure safe transit with standard packaging, and the delivery time of 30-90 days allows for efficient planning of manufacturing processes.

Customers can benefit from convenient payment terms including TT and L/C, while the supply ability of 100 lines ensures prompt availability for high demand. The HUASU Double Wall Corrugated Pipe Extrusion Line features high-quality components such as a barrel screw with a hardness of HV>740, ensuring durability and efficiency in operation.

Equipped with Siemens and Schnerder contactors, and gear material made of 20CrMnTi and screw material of 38CrMoALA, this equipment guarantees reliability and performance in producing corrugated pipes. Whether in construction, landscaping, or infrastructure development, the HUASU Double Wall Corrugated Pipe Extrusion Line is a valuable asset for any project requiring top-notch Corrugated Pipe Extrusion Production Line technology.