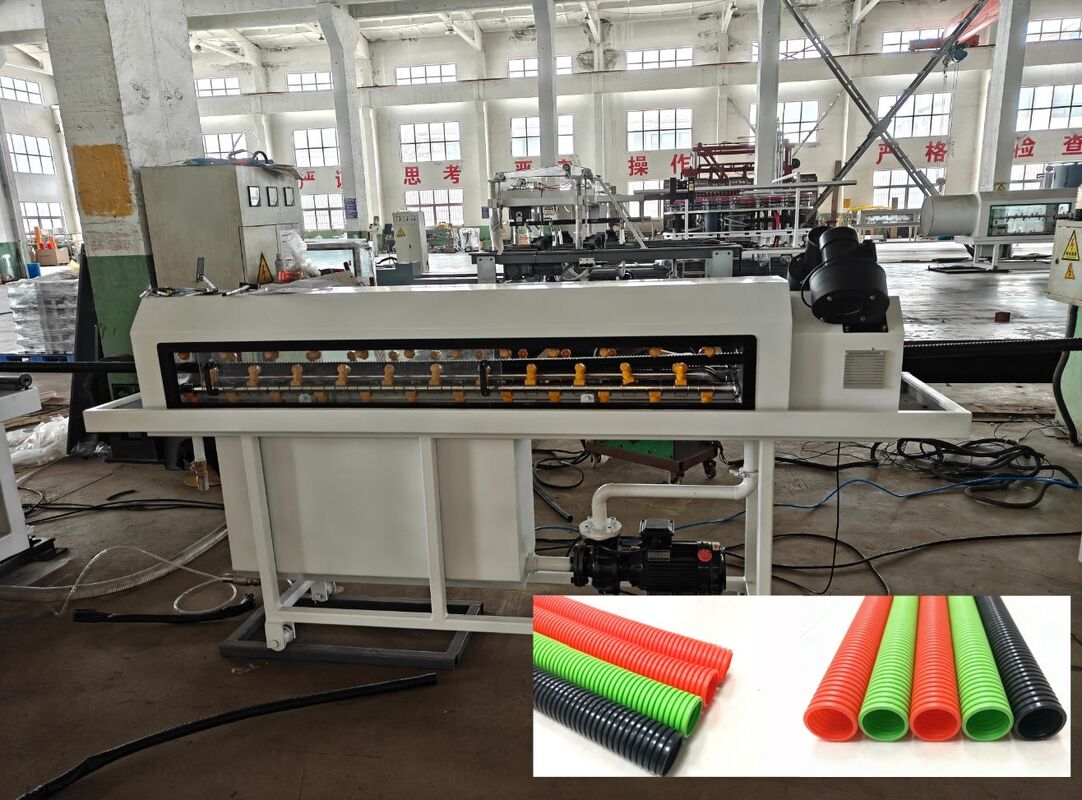

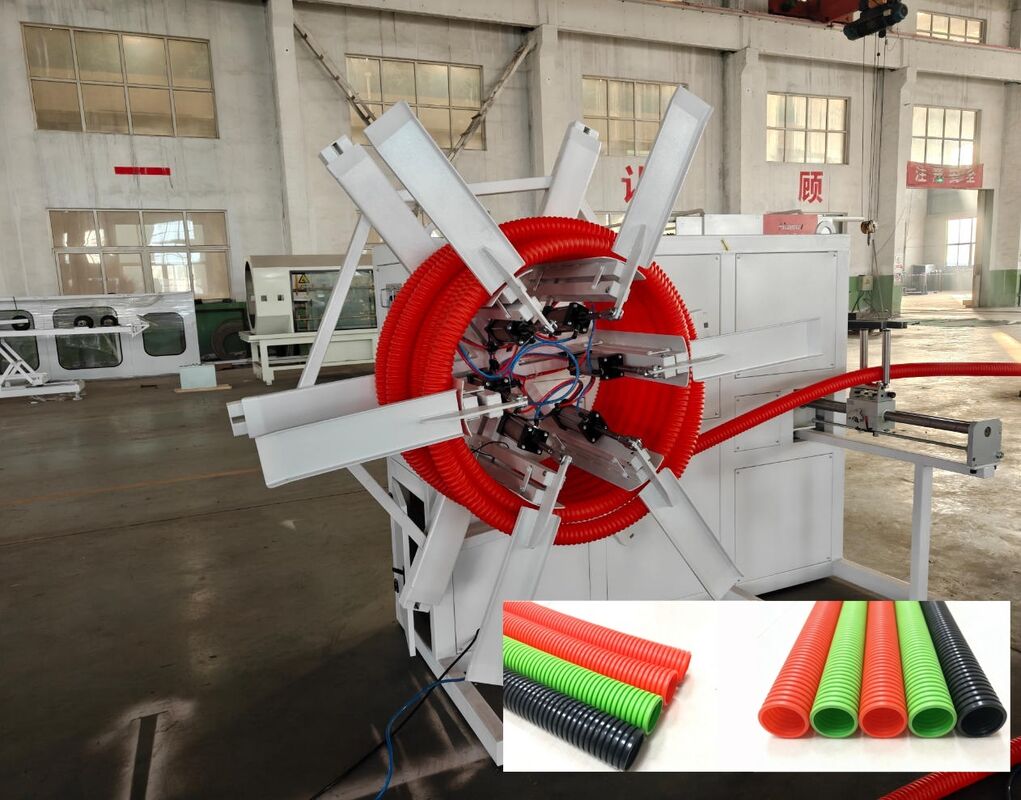

Single Wall Corrugated Pipe Production Line

Advanced Manufacturing with Hard Teeth Face Gearbox Technology

The Single Wall Corrugated Pipe Extrusion Line is engineered to meet demanding industrial requirements across agricultural irrigation, electrical cable protection, and general conduit applications. This state-of-the-art production system delivers high efficiency, precision manufacturing, and exceptional durability at competitive factory pricing.

At the core of this extrusion line is the deep screw channel structure, which enhances material melting and mixing processes. This design ensures thorough plasticization and homogenization, producing superior pipe quality with consistent wall thickness and mechanical strength—essential for agricultural irrigation applications requiring durability and flexibility.

The hard teeth face gearbox provides robust power transmission with reduced mechanical wear and maintenance needs. This technology offers excellent load capacity and noise reduction, supporting continuous large-scale production while minimizing operational costs.

Advanced electric heating with high-accuracy temperature sensors ensures precise thermal control during extrusion, preventing material degradation and maintaining consistent pipe quality. This precision manufacturing capability guarantees pipes meet exact specifications for diameter, wall thickness, and corrugation depth.

Key Features

Product Name: Single Wall Corrugated Pipe Extrusion Line

Heating Method: Electric Heating for efficient temperature control

Screw Channel Structure: Deep Screw design for optimal material processing

Motor: High-quality Siemens motor ensuring reliable performance

Gearbox: Hard Teeth Face gearbox for durable and stable operation

Guarantee Period: 1 Year warranty for peace of mind

Automation: Fully automatic operation for enhanced productivity

Application: Ideal for plastic corrugated pipe plant setups

Technical Specifications

| Parameter |

Specification |

| Guarantee Period |

1 Year |

| Screw Channel Structure |

Deep Screw |

| Heating Method |

Electric Heating |

| Gearbox |

Hard Teeth Face |

| Temperature Control |

Temperature Sensor |

| Key Selling Points |

High-Accuracy |

| Motor |

Siemens |

Applications & Specifications

The HUASU Single Wall Corrugated Pipe Extrusion Line (Model SBG) is certified with CE and ISO standards, ensuring compliance with international manufacturing regulations. With a minimum order quantity of 1 set and annual supply capacity of 100 sets, this system accommodates both small and large-scale production requirements.

Primary Applications:

- Urban infrastructure drainage systems

- Agricultural irrigation networks

- Electrical conduit and cable protection

- Industrial cable management solutions

- HDPE single wall corrugated pipe production

Additional Details: Container standard packaging ensures safe delivery within 60-90 days. Flexible payment options include T/T and L/C. Price range: USD 10,000 - 1,000,000. This versatile system can be adapted for HDPE double-wall corrugated pipe production with additional components.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews