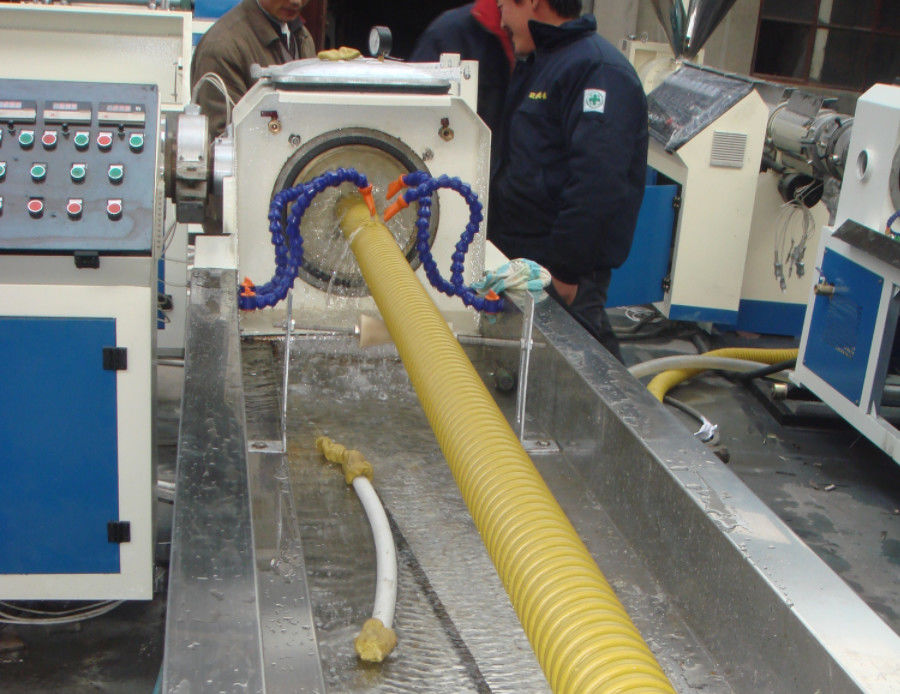

PE Carbon Spiral Pipe Machinery Nd Spiral Pipe Extrusion Line

- Application: electrical wire conduit and communication

- Pipe length: according the customer’s inquiry

- Recommended raw material: new material for PE pipe

Equipment Configuration

|

No.

|

Name & Model

|

Quantity

|

| 1.0 |

Single Screw Extruder SJ-65/30 |

1set |

| 2.0 |

Die head and Calibrator |

3sets |

| 3.0 |

Forming Machines STCJ—160 |

1set |

| 4.0 |

Haul—off Machine STLQ—160 |

1set |

| 5.0 |

Cutting Machine |

1set |

| 6.0 |

Winding Machine |

1set |

| 7.0 |

Control system |

1set |

| Power |

380 V x 60 Hz x 3 Phase |

| Total Power |

55kw |

| Cooling Water |

Recycling water. ≤20℃, ≥0.3Mpa, ~3T/h |

| Compressed air |

0.3m3/min, >0.5Mpa |

| Line Dimension |

18m×2.7m×2.5m |

PE carbon spiral pipe production line is widely used:

The unit produces PE carbon spiral pipe, mainly used for (light) cable jacket protection, and gradually applied to the power, telecommunications, postal services and highways, ports and other infrastructure areas.

PE carbon spiral pipe production line features:

1) configuration of polyolefin dedicated single screw extruder, with high-speed extrusion, high speed and so on.

2) Dedicated separate mixing screw and spiral structure of the nose, the flow channel is reasonable, smooth inside and outside the pipe.

3) Specially designed sizing Cooling method: The production range is 30-200mm, the production speed is as high as 0.8-4m / min.

4) standard design of the pipe head

5) Spiral distribution of split fluid, large flow space, to ensure that the melt has enough time to stay.

6) the best design of low melting temperature, the pipe of the internal stress is small, smooth inside and outside the surface.

7) High flexibility, suitable for all polyolefin materials coextrusion, can be extruded two, three different specifications of the use of spiral reinforcement tube.

8) Optimized design of copper helix sizing inlet with a pre-cooling device and a strong suction vacuum device for high-speed extrusion of the pipe

9) Specially designed sprinklers bring efficient spray cooling.

10) vertical movement motor adjustment, up and down about three-dimensional adjustment can be achieved. The following are the same as the "

11) The cabinet is made of stainless steel.

12) High efficiency pumps and special sprinklers bring efficient spray cooling.

HDPE Carbon Helical Casing Equipment, Carbon Tube Production Equipment, PE Carbon Spiral Pipe Equipment, Carbon Bellows Equipment, Carbon Spiral Pipe Equipment Carbon Tube Equipment Prestressed Pipe Equipment

Other plastic pipe production line

PE, PP , and PVC single wall corrugated pipe extrusion line with high speed and stable running.

HDPE single wall corrugate pipe machine PP/PE/PVC/EVA/PA single wall corrugated pipe machine.we developed the mahcine on the basis of traditional structure, we give new designing on the forming table, we adopt SJ 45 SJ 65 SJ 90 to produce different range pipe diameter. our machine easy to operate, stable running, we provide long term after sell service.

PP,PE single wall corrugated pipe machine can be used to produce corrugated pipes of PE,PP,PVC,EVA continuously,as well as PA corrugated pipes. Plastic single-wall corrugated pipes have features of high temperature resistance, resistant to corrosion and abrasion, high intensity, good flexibility, etc. They are widely used in fields of auto wire, electric thread-passing pipes, circuit of machine tool, protective pipes of lamps and lanterns wire, tubes of air conditioner and washing machine, etc.

SBG series plastic single-wall corrugated pipe production line developed by our company adopts gears to run moulds and templates so as to realize water circulating cooling and air cooling of the products, which ensures high-speed molding, even corrugation, smooth inner and outer pipe wall. These corrugated pipes are especially used as wires of the up-market cars.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!